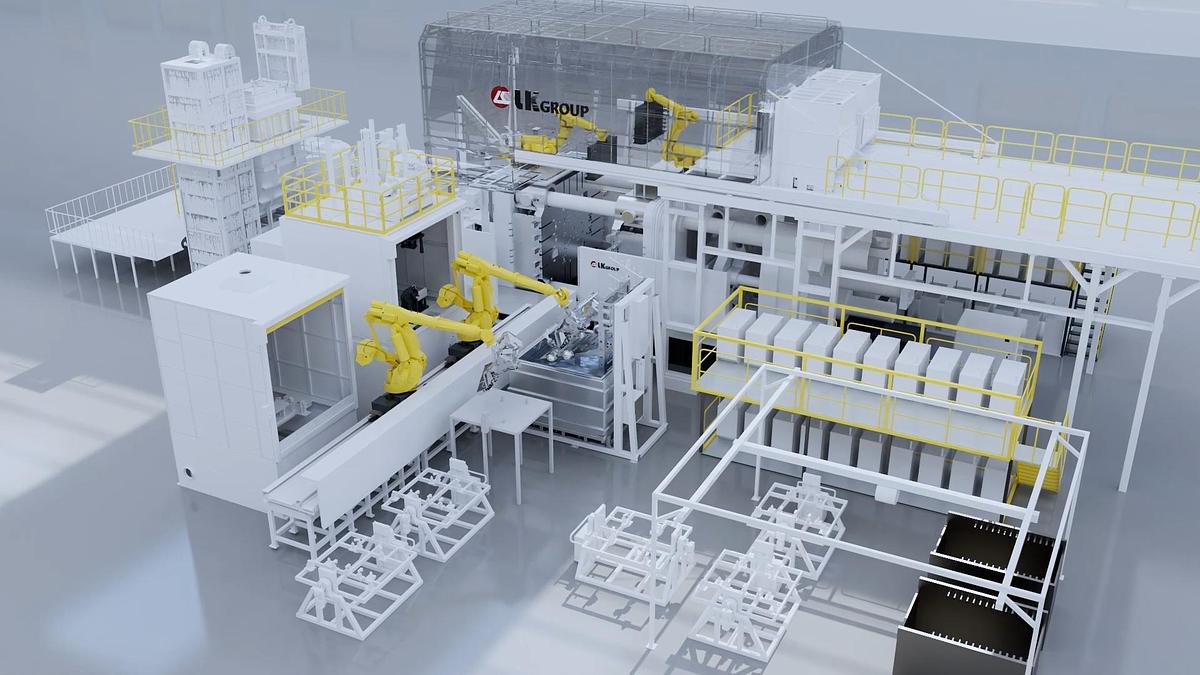

Die Casting Products Automation Solution

Contact us for price

Description

For intelligent die casting clients, LK Group provides a comprehensive range of services encompassing entire plant solution planning, intelligent water, electricity, and gas supply, centralized material feeding, design and manufacturing of robots and robotic arms, automation solutions, digitalization of workshops, virtual simulation of the entire plant, project implementation management and control, as well as technical service support.

Whole Plant Virtual Simulation

By integrating virtual reality technology with clients' plants, LK Group conducts modeling and simulation of industrial processes and workflows, enabling three-dimensional visual simulation of industrial processes. Based on clients' actual situations, it realizes process simulation, plant simulation, logistics simulation technology, and sensor technology. Combined with actual intelligent manufacturing production lines, it achieves simulations of numerical control processing, inspection, assembly, and other processes.

Whole Plant Planning Scheme

LK Group provides customized plant planning for clients, offering targeted and customized solutions for optimizing the entire plant production process, including lean plant layout, intelligent water, electricity, and gas layout, intelligent centralized material supply, automation scheme design, and intelligent logistics planning. These solutions possess higher rationality.

Automation Solutions

LK Group provides complete plant automation solutions for various industries, mainly covering automotive components, logistics pallets, optical lenses, daily chemical products, home appliances, etc.

On-site Project Management and Control

LK Group implements comprehensive project management, planning, organizing, implementing, supervising, and controlling projects to ensure that clients have a thorough understanding of project dynamics and real-time situations throughout the project process.

Specifications

| Manufacturer | LK |

| Condition | New |