GM Series

Description

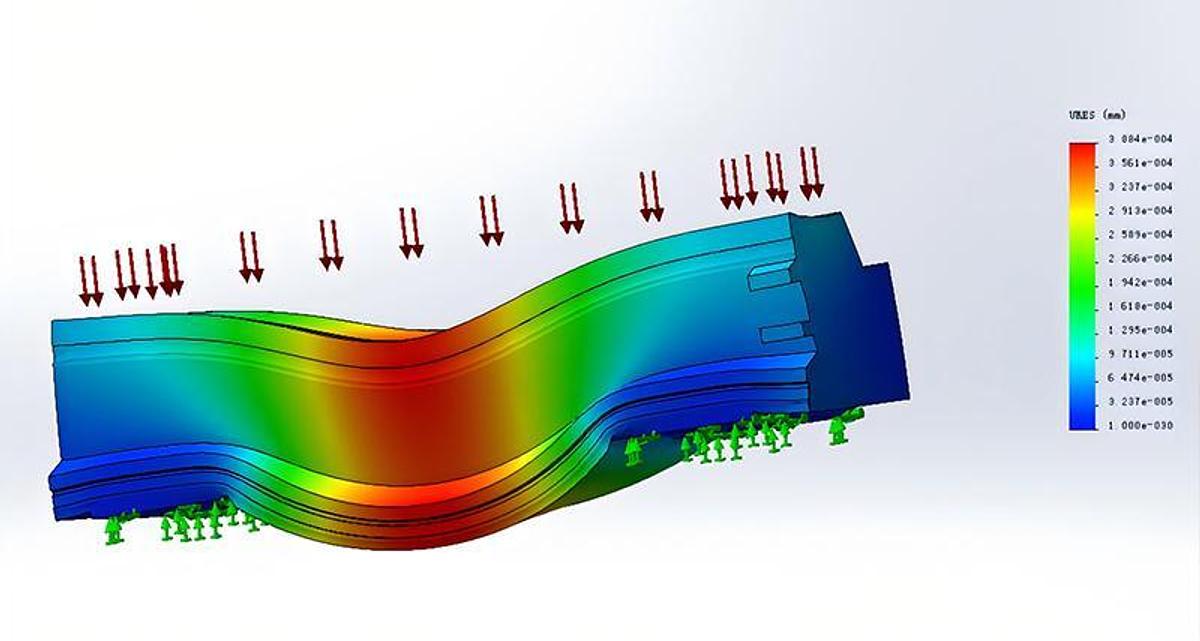

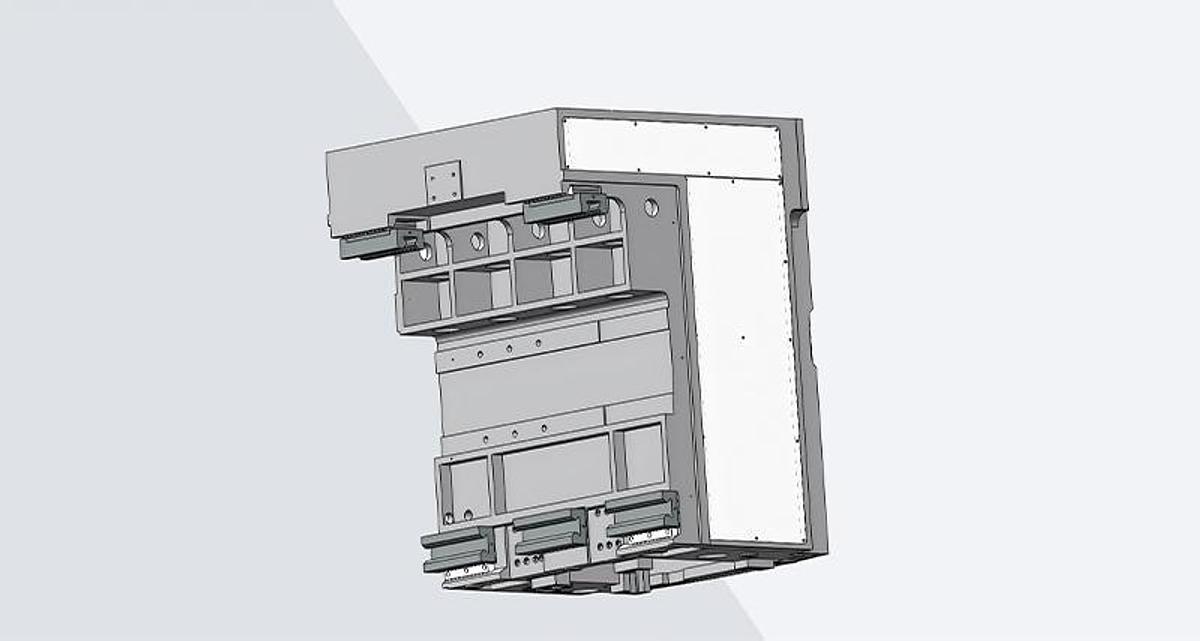

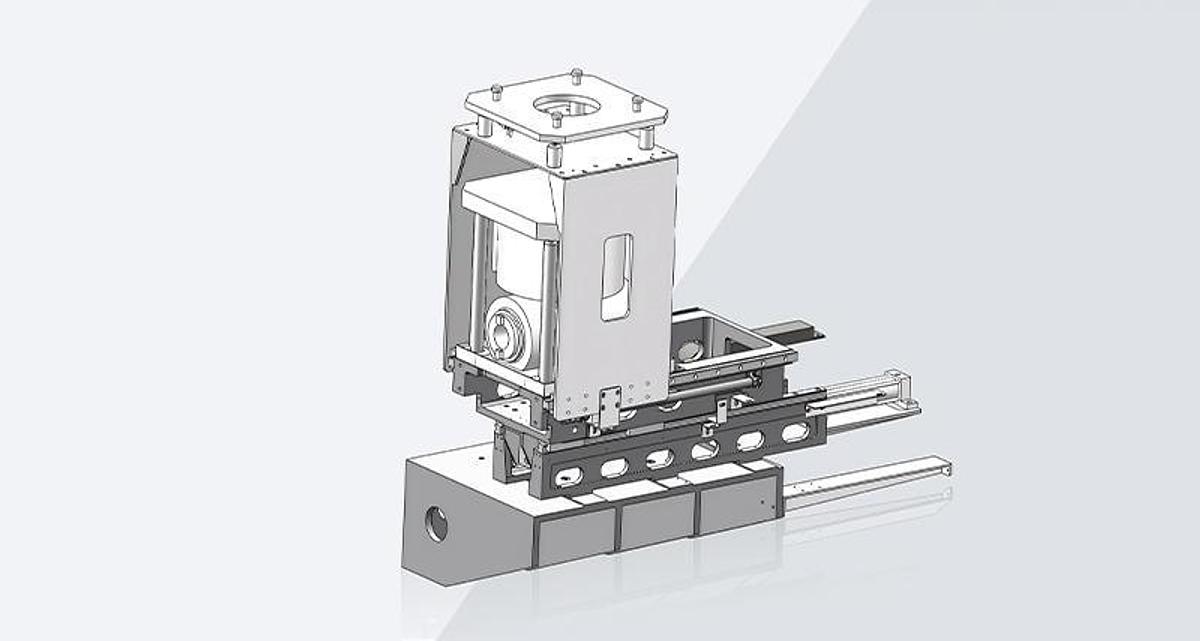

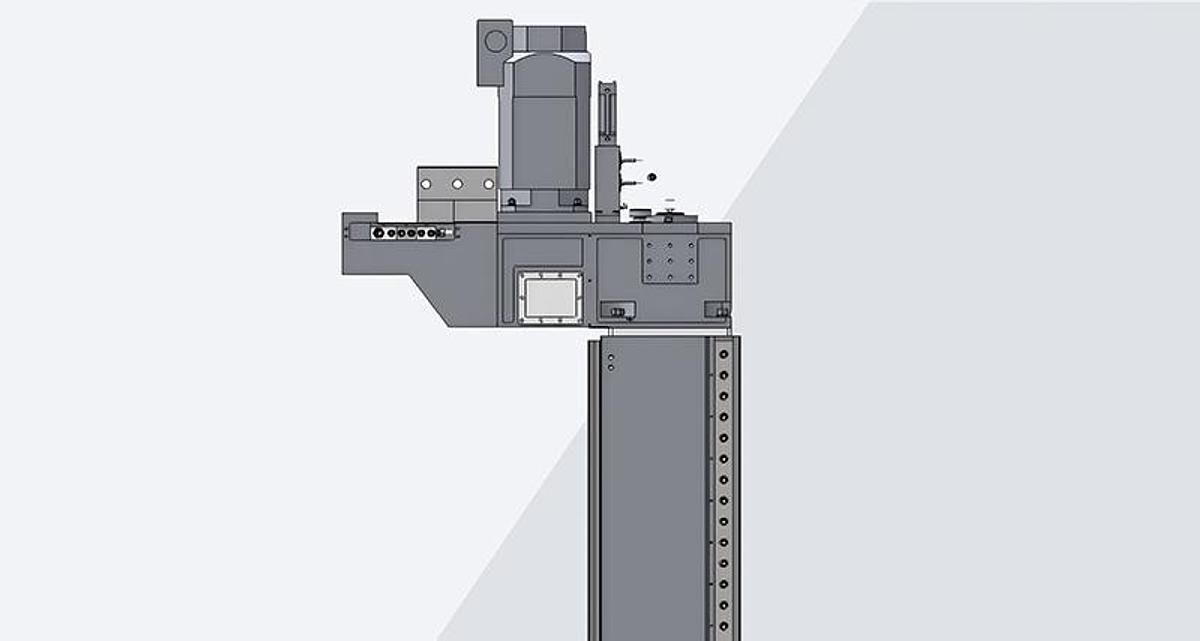

The GM series of CNC gantry machining centers inherit the advantages of traditional gantry machine tool processing. The design fully considers the internal reinforcement structure of each component, as well as high rigidity and dynamic characteristics, to meet the cutting requirements of high power and torque. It is suitable for processing materials such as ferrous metals, cast iron, steel, etc. Meanwhile, it can handle the processing of complex parts with multiple angles and five surfaces, catering to the processing needs of industries such as shipbuilding, mold making, engineering equipment, and rail transit. Compact Fixed Table and Beam Design The GM series machines adopt an overall structure with a fixed table, fixed beam, and movable column, reducing the overall footprint of the product. Precision Casting Design The main castings of the machine tool have undergone finite element analysis to ensure the rationality of casting structure and internal reinforcement layout, achieving a good balance between machine weight and overall rigidity. Optimized Saddle Structure The saddle adopts a structure with three sliders on the lower side and a lower guide rail positioning system, which is closer to the processing area. This design can better overcome cutting forces and reduce the impact of machine tool vibrations. Innovative Attachment Tool Storage The machine tools are designed with attachment storage compartments, facilitating automatic switching between vertical and horizontal spindles. Powerful Cutting Capability Equipped with a gearbox with a larger reduction ratio, the machine tool can perform powerful cutting operations.

Specifications

| Manufacturer | LK |

| Condition | New |

| Stock Number | 00083 |