LT Series

Contact us for price

Description

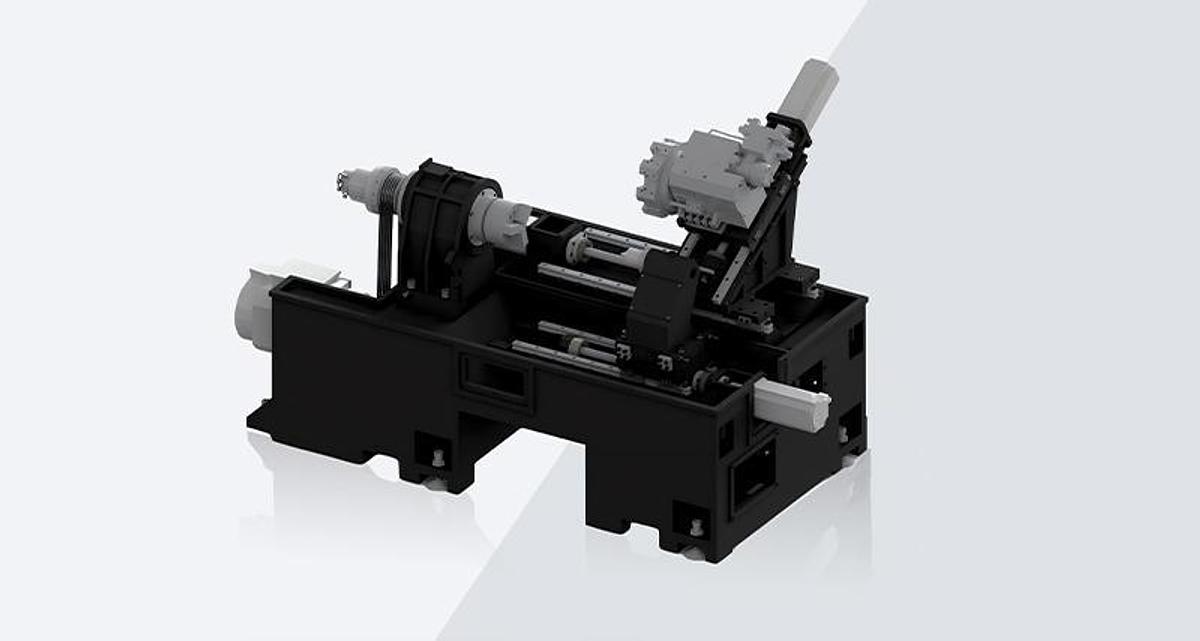

The LT series of CNC horizontal lathes adopt an integral bed structure with the X-axis inclined at a 30-degree angle to the horizontal plane, offering a small footprint, compact and reasonable overall layout, smooth chip evacuation, and convenient operation. The guideways are rolling types, and the drive components use high-speed, high-rigidity ball screws, featuring fast speeds, low heat generation, and high positioning accuracy. The machine is fully enclosed for protection, with automatic chip evacuation, lubrication, and cooling. It is suitable for processing various complex-shaped axles, sleeves, and disks, such as turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooving, chamfering, drilling, reaming, and threading.

Machine Tool Structure

The machine tool adopts an advanced 30° high-low compound slant bed structure, achieving minimal footprint while maintaining excellent rigidity and precision retention performance.

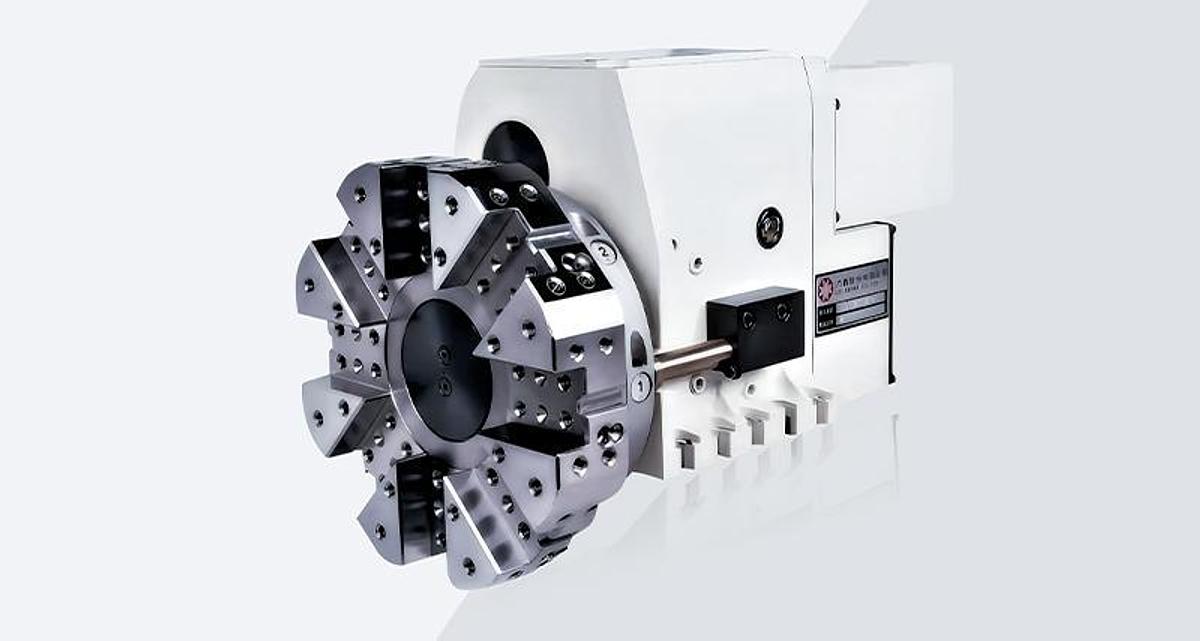

ROBUST Structure for Spindle Bearings

The spindle employs a belt-type sleeve spindle unit for easy installation and maintenance. The spindle bearings feature the ROBUST structure: the front end consists of double-row cylindrical roller bearings and double-row angular contact thrust ball bearings, while the rear end uses double-row cylindrical roller bearings. This ensures high rigidity and stability of the spindle. The spindle is driven by a servo motor, guaranteeing the need for cutting at both high and low speeds.

Powerful Cutting

The tool turret utilizes servo motor indexing, gear plate positioning, hydraulic clamping, and releasing technologies, ensuring fast indexing speed and rigid clamping, making it suitable for powerful cutting operations.

Specifications

| Manufacturer | LK |

| Condition | New |