LH Series

Description

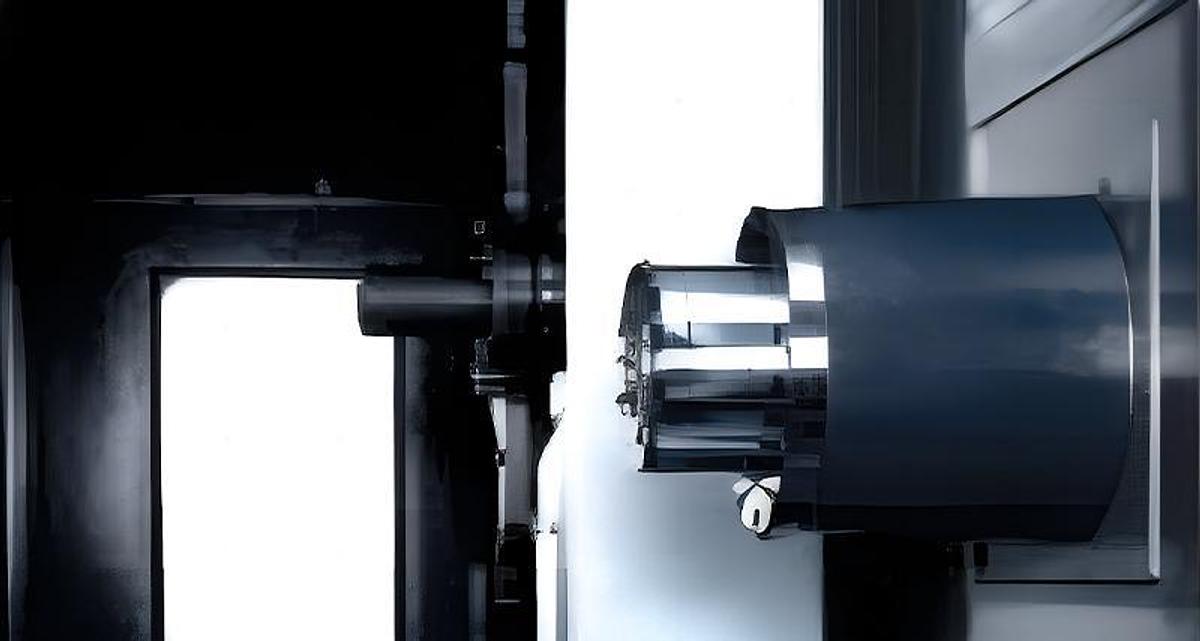

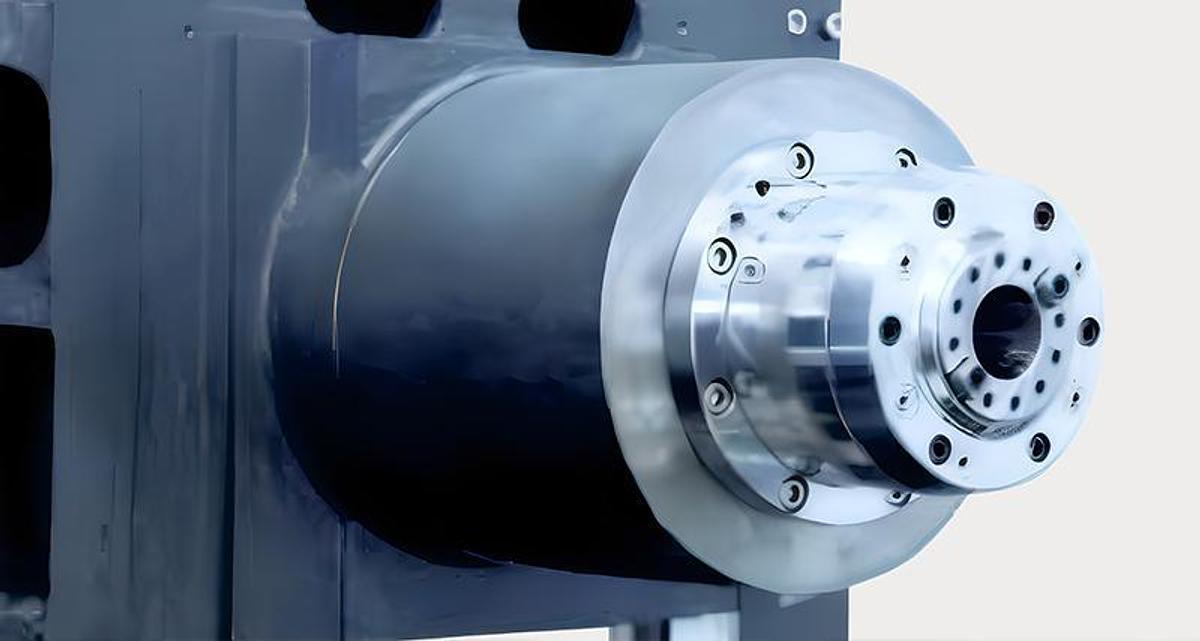

Featuring high rigidity and high-speed processing, the LH-500 is lightweight.Its rapid feed speed is over 20% faster than traditional models, and the machine structure utilizes a rear-wall high-rigidity bed.From low-speed casting processing to high-speed aluminum alloy processing, it meets the diverse needs of various industries, led by the automotive industry. High-Rigidity Bed By positioning the linear guides of the X-axis and Z-axis at an elevated level, a high-rigidity bed with substantial wall thickness is achieved. High-Rigidity Machining By reducing the minimum distance from the spindle face to the pallet center by 84mm, shorter tools can be utilized, enabling higher-rigidity machining. Spindle Bearing Inner Diameter The inner diameter of the spindle bearing has been increased to enhance rigidity. Additionally, the spindle drive employs a direct-coupled spindle capable of delivering maximum output power over a wide range. ATC Cam Mechanism The ATC cam mechanism incorporates a frequency converter to increase tool change reliability, allowing for multi-stage speed adjustments. By securing the tool with a retaining lever, even long and heavy tools can be firmly grasped, ensuring reliable tool exchange.

Specifications

| Manufacturer | LK |

| Condition | New |

| Stock Number | 00051 |