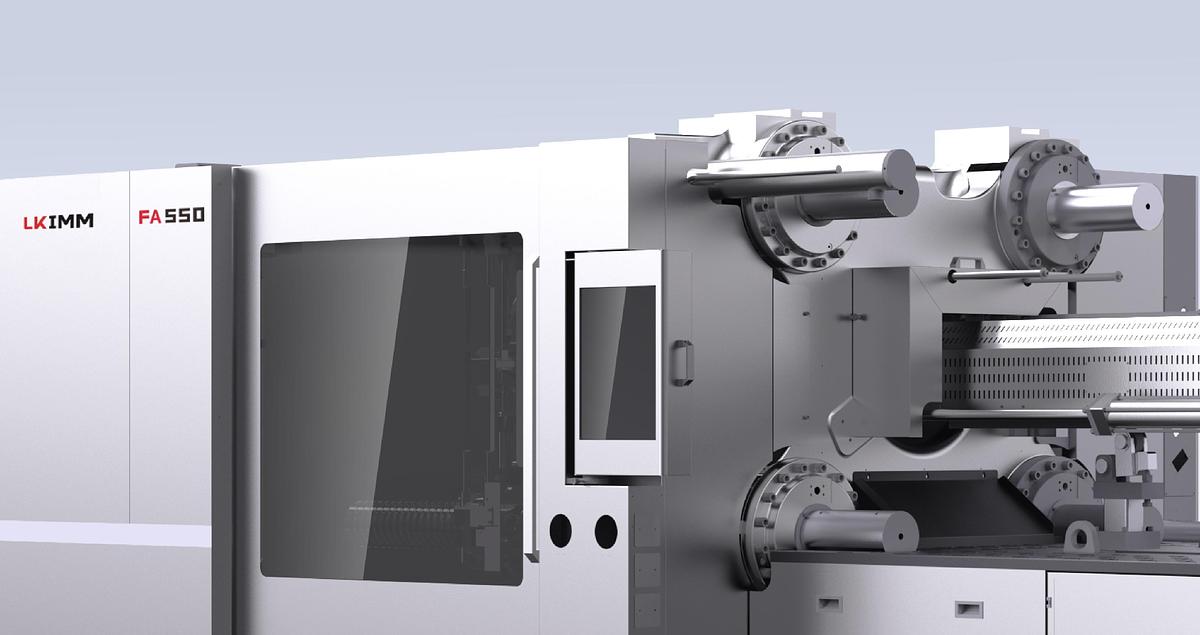

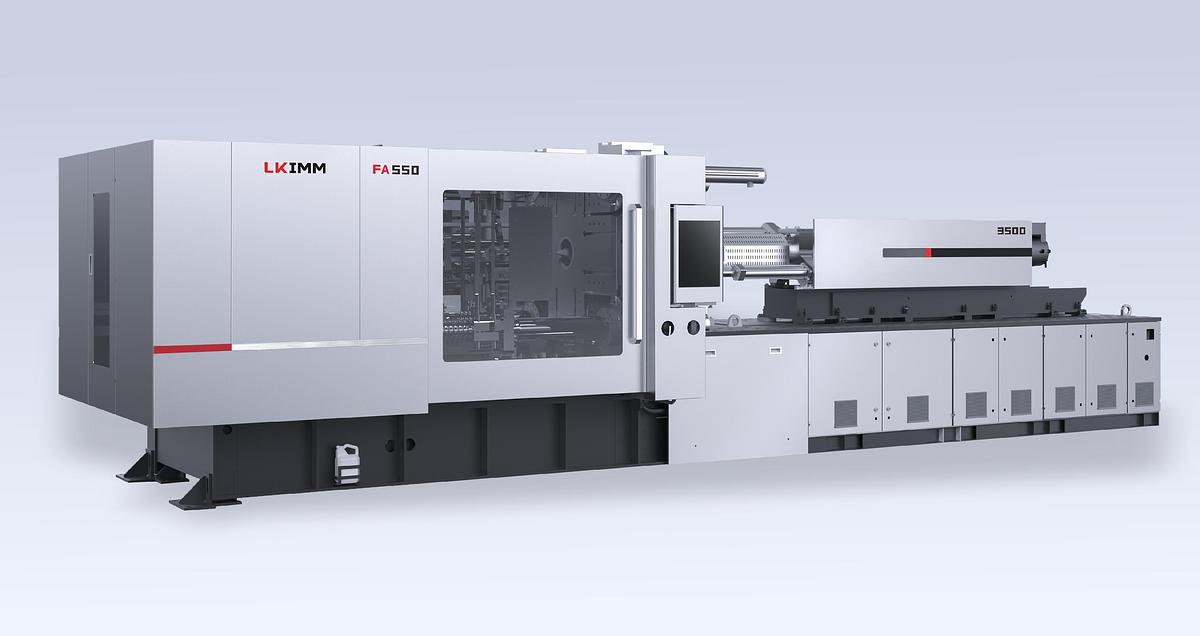

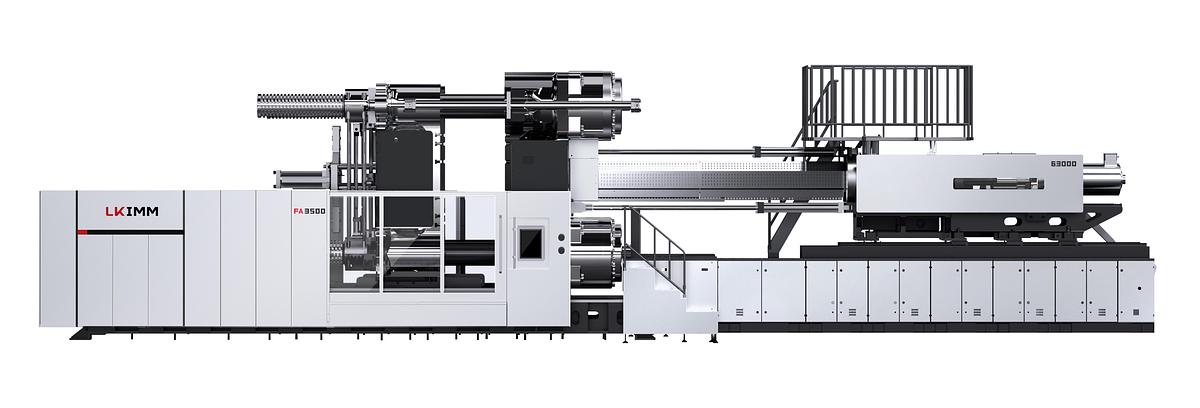

FORZA series

Contact us for price

Description

The FORZA series adopts a single-cylinder injection system, which has a fast response and high injection accuracy. The whole machine has a compact structure, a small floor area, a large mold space, and the clamping force ranges from 4500 to 70000 KN. It can excellently meet the requirements for components with high surface quality in the home appliance industry, high-precision parts in the automotive industry, garbage classification sanitation bins, pallets and turnover boxes in the logistics industry, and civilian industries and other application fields. The FORZA two-platen injection molding machine can provide an overall injection molding solution.

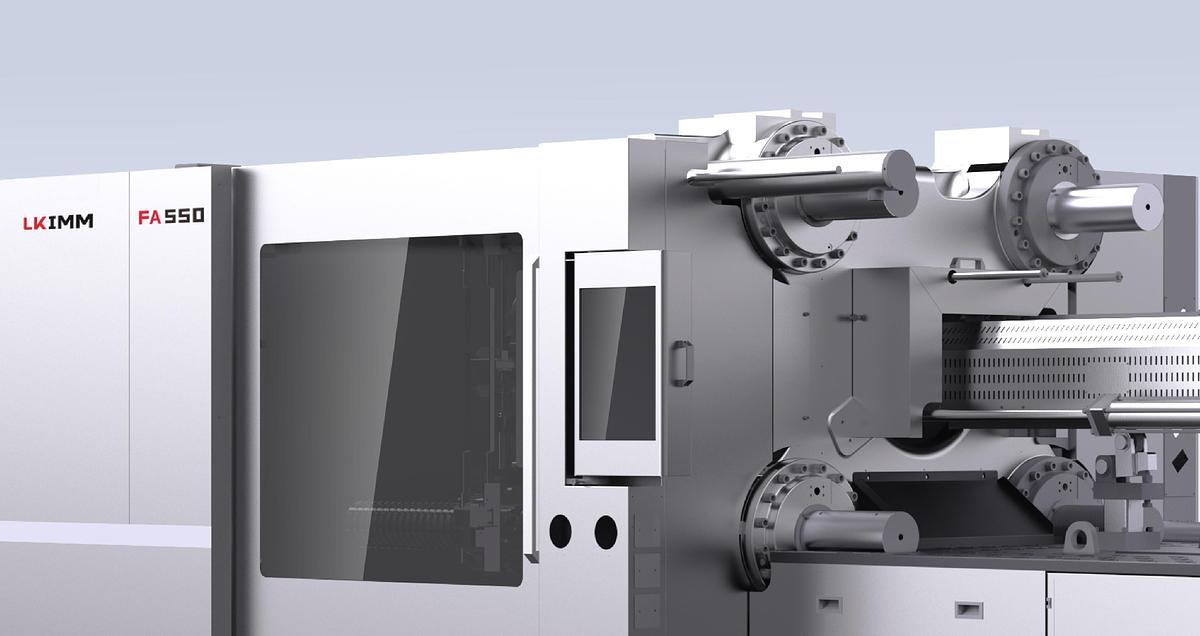

Unique single-cylinder injection system

Small inertia, high injection accuracy, fast injection speed, and stable operation.

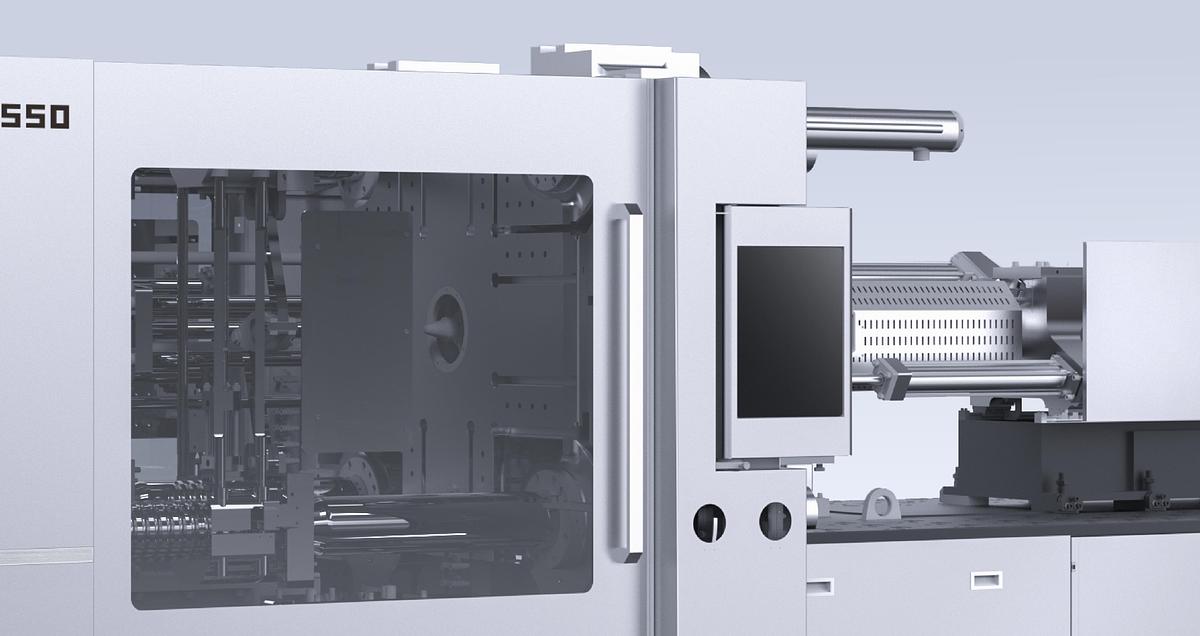

More stable and faster clamping unit

The electronic proportional valve is used to control the mold opening and closing, with high repeat accuracy; the standard synchronous ejector pins or core-pulling are equipped, which greatly shortens the cycle time. The displacement adopts high-precision position transducer.

Controlled by the European KEBA computer system

Adopted by KEBA European professional computer control, centralized intelligent management; expandable module group, centralized control processing of the robotic arm, intelligent connection with external equipment, and centralized control.

Two-platen type compact space advantage

Compact clamping unit structure design, saving floor space.

Synchronous nut locking mechanism, uniform distribution of clamping force

Realize synchronous nut locking, with high reliability, stability and durability.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 450-7000 |