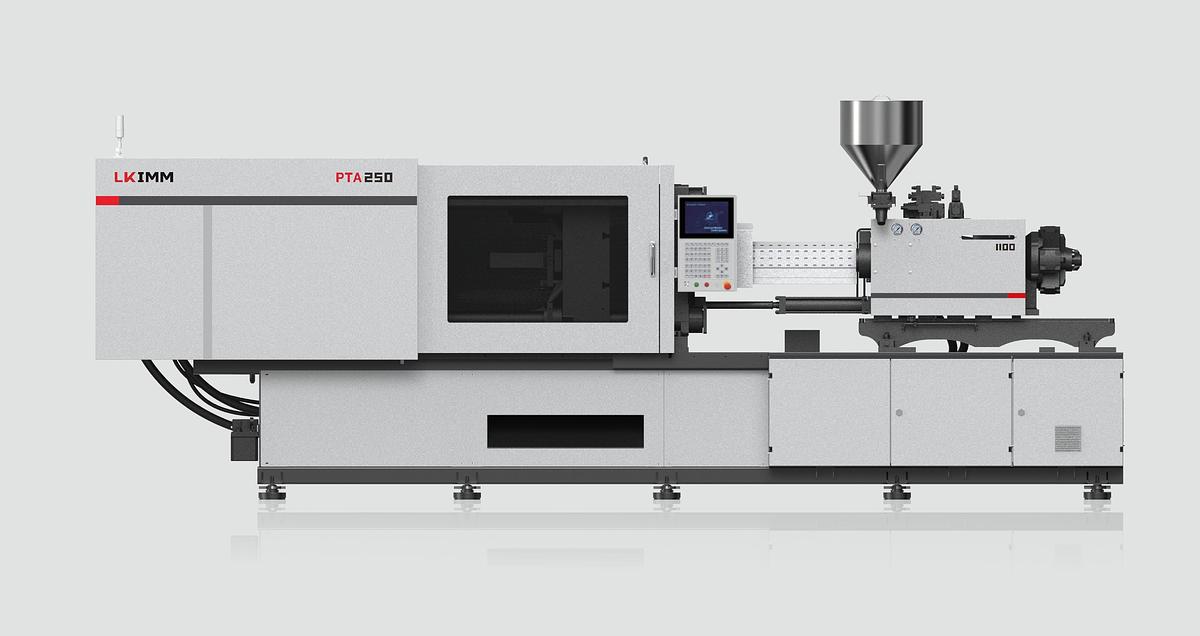

POTENZA-A series

Contact us for price

Description

The LK POTENZA-A servo injection molding machine incorporates new technologies, new processes and new concepts on the basis of inheriting LK's traditional design concepts, making the overall performance of the machine more advanced and perfect. The user-friendly appearance and safety design in line with national standards make the machine operation safer and more reliable; the professional injection molding machine computer control system has a fast response cycle and is easy to operate.

High-Performance Clamping Unit

All parts of the clamping unit are manufactured by a single-pass CNC machining process, ensuring high accuracy.The toggle shafts and steel bushings are made of Japan-imported alloy materials and undergo special heat treatment, resulting in high wear resistance and long service life.The platens are designed by finite element analysis, featuring a more reasonable structure and process, as well as excellent rigidity and high strength.The quick-change ejector with forced ejector reset function fully meets the ejection and resetting requirements of various molds, with easy operation and smooth movement.

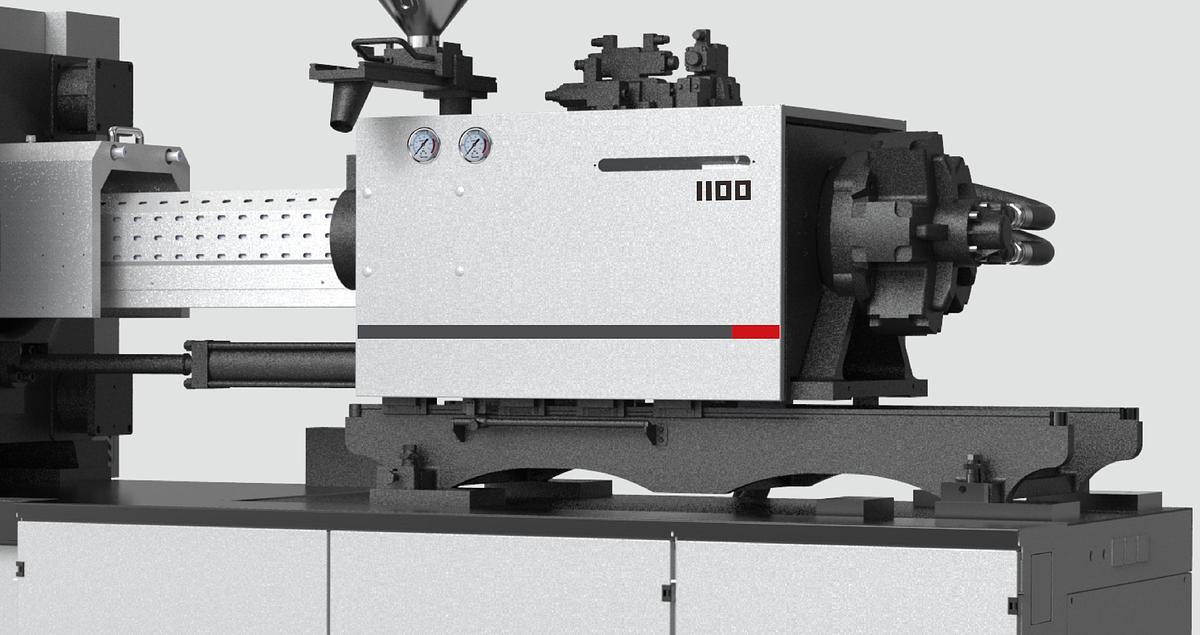

High-Precision Injection Unit

The injection unit adopts linear guides, ensuring precise injection and plasticizing positions.The carriage is supported by an integral arch design, guaranteeing long-term stability during machine operation.The dual-cylinder balanced injection system is optimized for more stable and reliable injection performance.

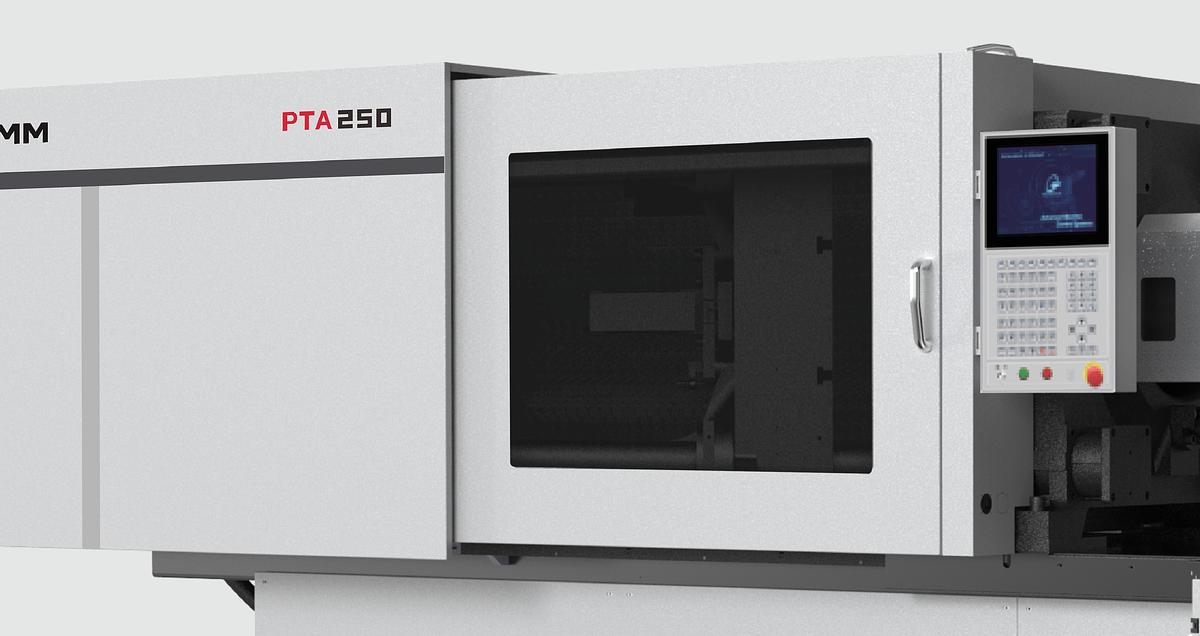

Intelligent Electronic Control Unit

The adoption of functions such as intelligent mold opening and closing, temperature self-learning, and multi-stage control of oil pressure and flow effectively enhances production accuracy and efficiency.It features higher sampling accuracy and higher control accuracy.The intelligent mold opening and closing algorithm automatically compensates for factors, simplifying commissioning and effectively mitigating the impact of oil temperature and lubrication.Intelligent multi-stage control of oil pressure operations optimizes control based on actual conditions, reducing flow waste, minimizing hydraulic impact, and lowering energy consumption.

High-Efficiency Power Unit

The new generation of high-performance IPM motor offers rapid response and stable operation.Combined with intelligent hydraulic position closed-loop algorithms, it significantly improves positioning accuracy, reduces impact during operation, and lowers machine wear and tear.Through optimized algorithms, it drastically decreases motor speed fluctuations and enhances the stability of the pressure loop.

Adding Cloud Injection Molding Networking Interface

The adoption of networking hardware interfaces facilitates machine networking and connection.Optional OPC Ua communication protocol offers effective cloud injection molding.Network access enables interconnectivity between machine data and the Cloud.

Brand-new Appearance and UI Design

The 12.1-inch LCD display is standard across the entire series.Brand-new frame design features a compact structure and strong scalability.All-new sheet metal exterior design is aesthetically pleasing and elegant.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 80-850 |