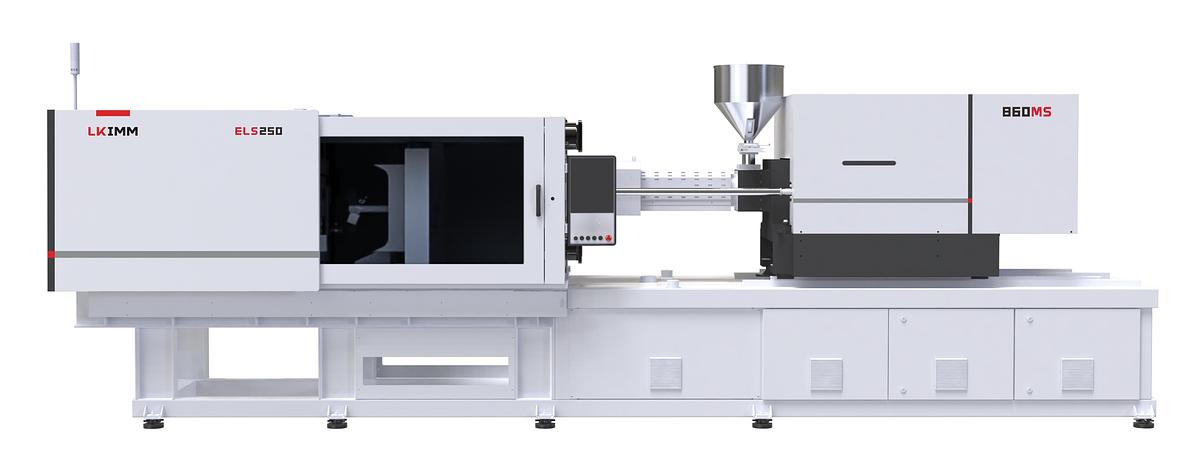

ELETTRICA-S series

Contact us for price

Description

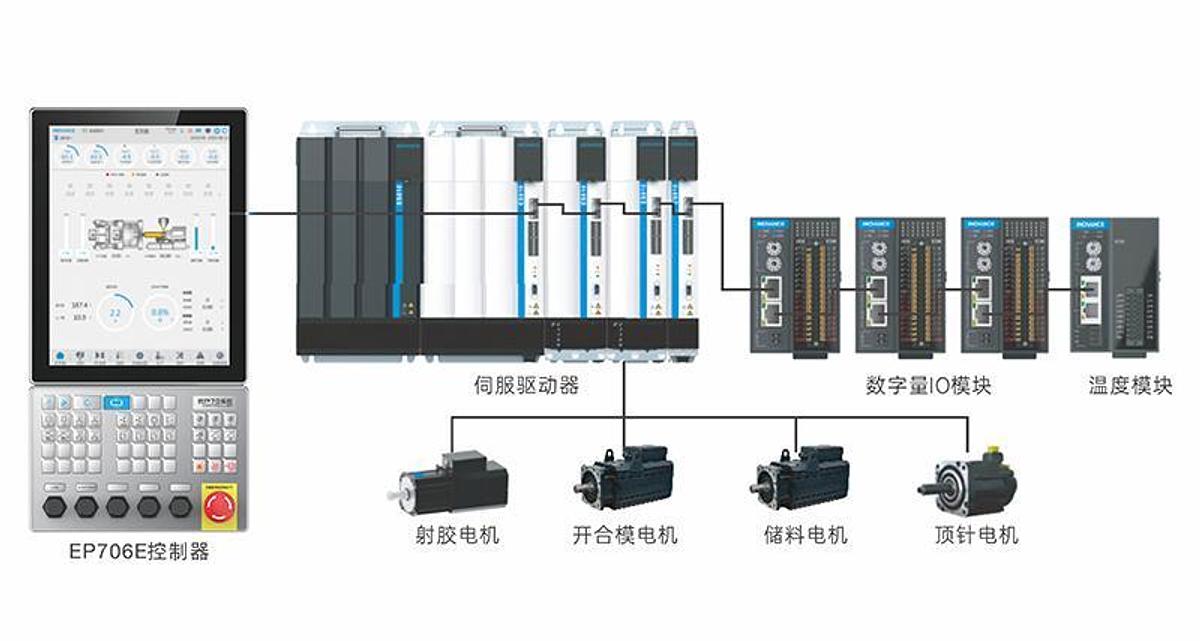

The ELETTRICA-S series adopts a brand-new high-drive system, combined with a professional control system, flexibly achieving precise and efficient injection molding. It has strong scalability, is equipped with a high-performance computer with an Intel X86 processor, and has an open international interface. The clamping force ranges from 1600 to 4500 KN and is widely applied in industries such as electronic communication, medical consumables, auto parts, packaging products, toys, etc.

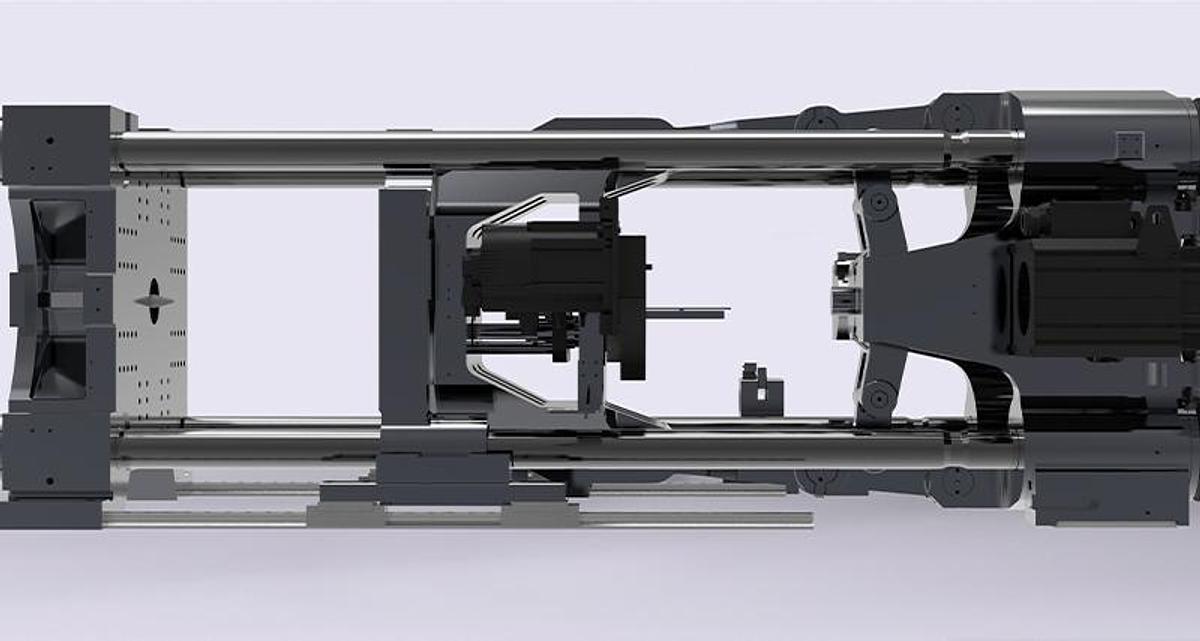

Clamping unit

Based on the platen and frame design optimized by professional finite element software, the strength has been further improved, stress concentration has been reduced, and deformation has been decreased, ensuring the requirements of high-precision mold locking and long-term durability.By adopting high-strength tie bars and servo motor drive technology, precise regulation of the clamping force with high efficiency and energy saving has been achieved.The unique electric ejection design not only improves the ejection accuracy and response speed, but also effectively enhances the overall working efficiency.

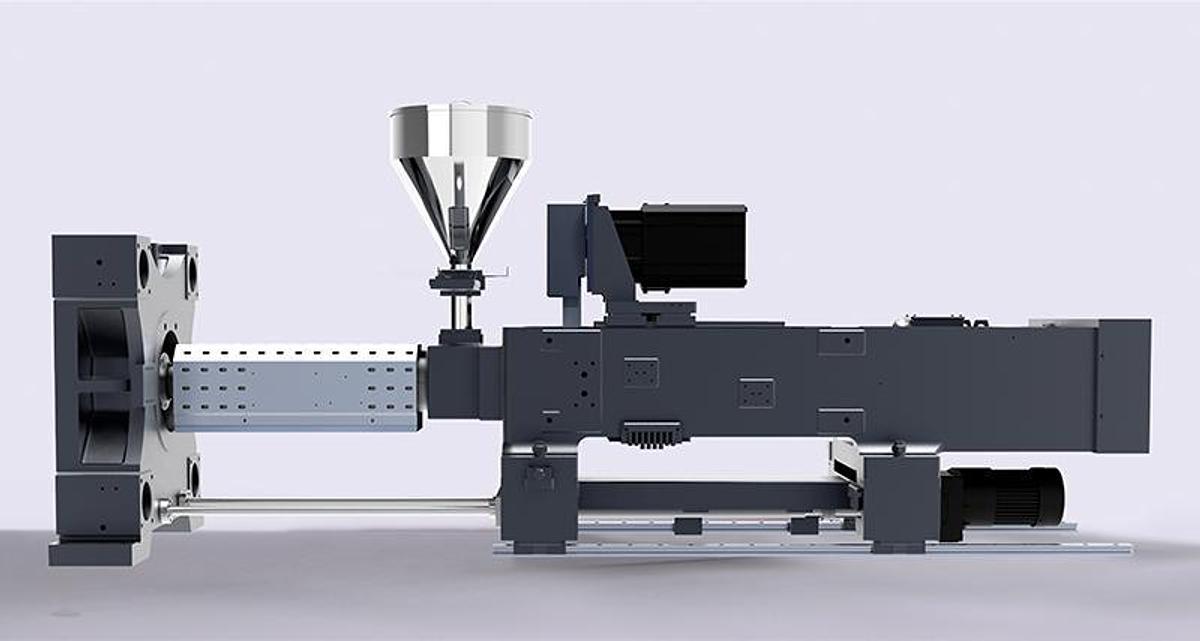

Injection unit

With a ±0.1% deviation control of the product weight, it not only saves costs but also ensures high quality. The production efficiency has been increased by up to 30%, fully meeting the demand for high-speed production. The flexible multi-stage injection technology effectively solves the yellowing problem caused by raw material retention.

Other highlights

Compact layout further saves spaceAdopts a brand-new digital control system with a more user-friendly operation interface and logically clear operation procedures.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 160-450 |