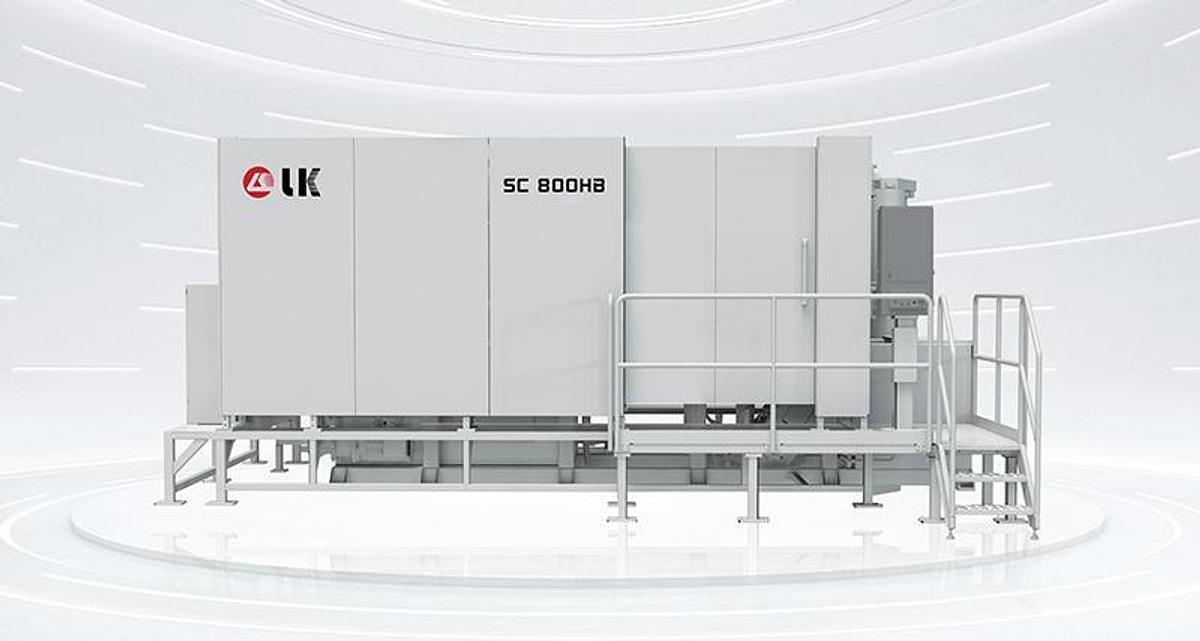

SC-H series

Contact us for price

Description

The SC-H series squeeze casting machine adopts a horizontal die closing design structure. It is an squeeze casting machine that integrates high-efficiency die transmission technology, squeezing full closed-loop real-time control technology, and intelligent production process control technology. This equipment is specially designed for castings with high quality requirements and can provide excellent solutions for the production of precision castings.

Higher casting production efficiency

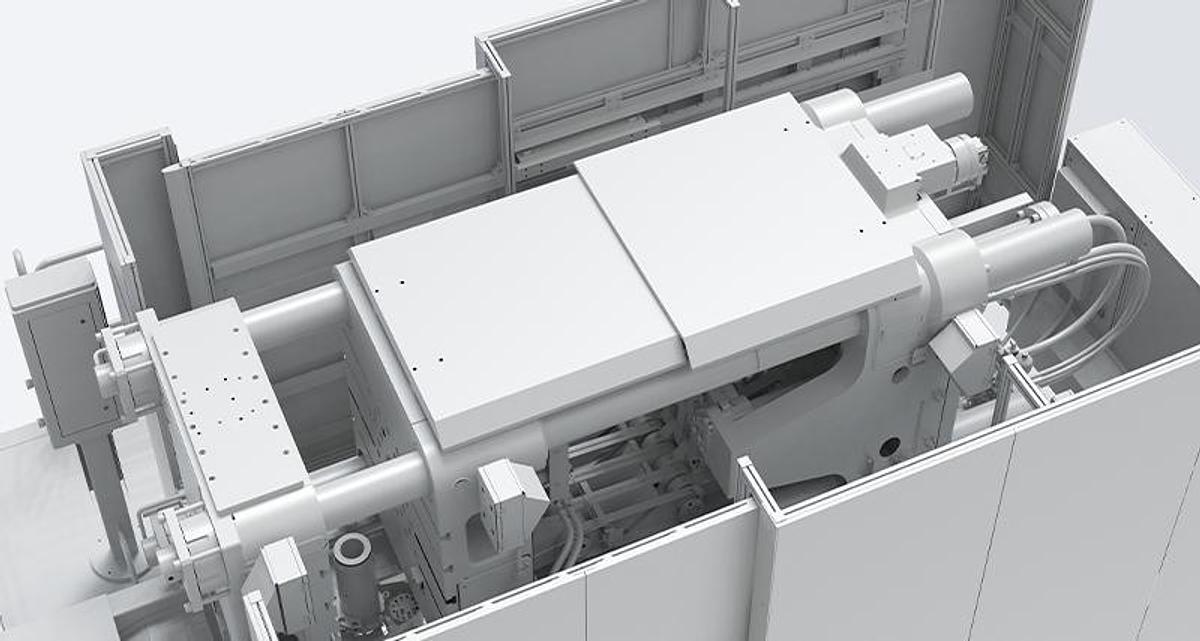

The efficient die closing transmission system greatly improves the transmission efficiency and effectively improves the production efficiency of castings.The movable platen can stop at any position with repeated accuracy ±2mm as advanced die closing hydraulic system and electric control system are adopted.The intelligent die height adjustment function enables one-click automatic and precise adjustment to the required clamping force, effectively saving adjustment time.

More comprehensive safety protection

Multiple safety protection systems, locking unit is equipped with hydraulic safety valves, light curtains, system redundancy control, etc.

Higher casting pass rate

The dual closed-loop real-time control function of speed and pressure.High-performance and high-repeatability real-time squeeze control system.Equipped with a production management system with the function of monitoring the quality of castings.All-round temperature field monitoring function.Configured with Siemens S7-1500 series high-speed controllers and adopts a distributed I/O control system.

Higher equipment stability and service life

The closed-loop control system automatically adjusts the clamping force out of tolerance when there is a thermal die deviation.The three-platen structure design optimized by CAE has reasonable stress distribution, and the surface adopts laser quenching and hardening technology.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 300-5000 |