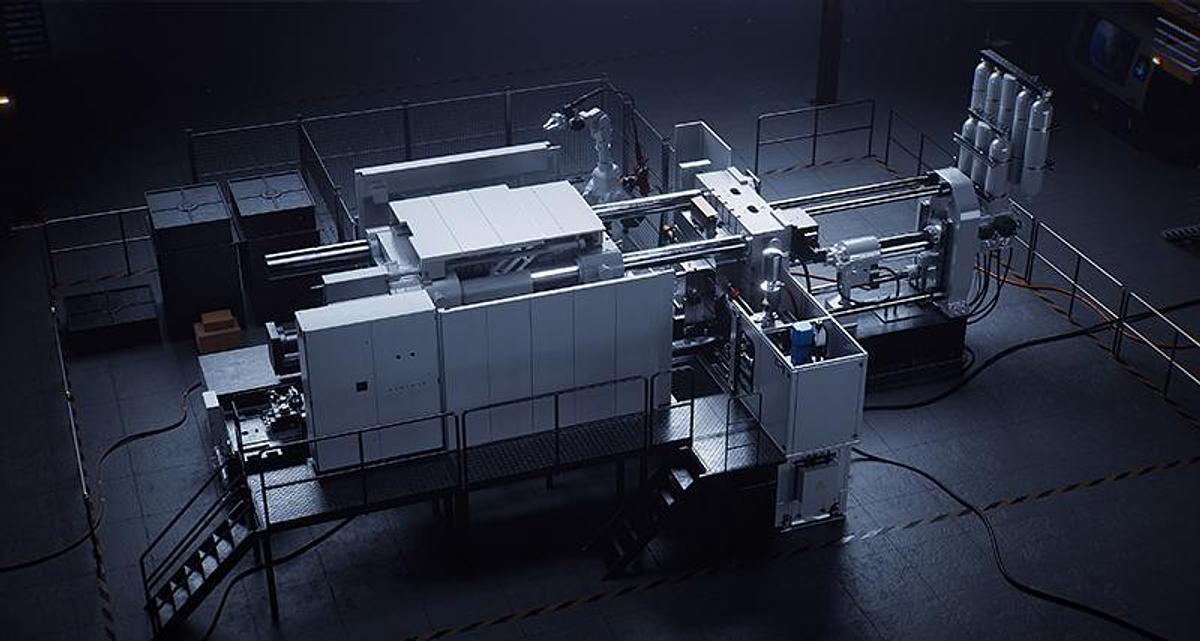

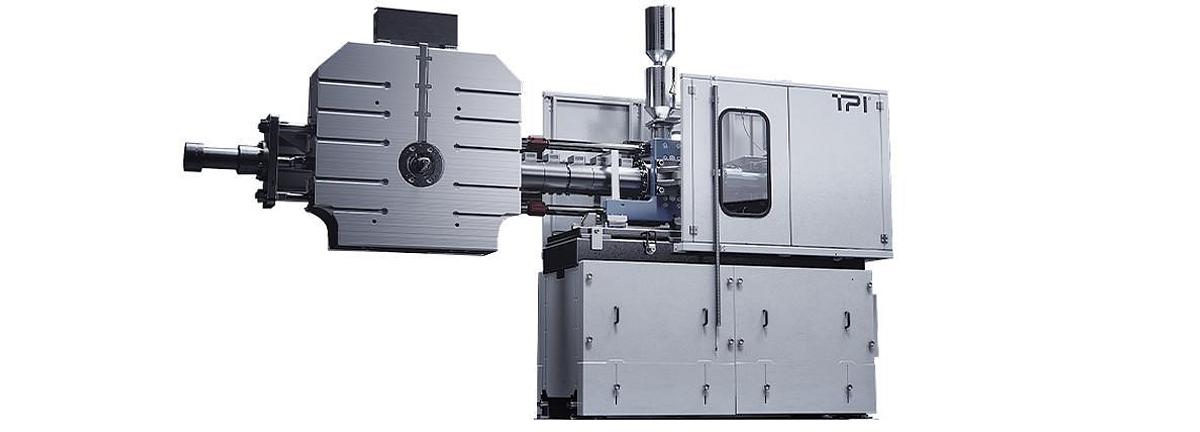

TPI series

Contact us for price

Description

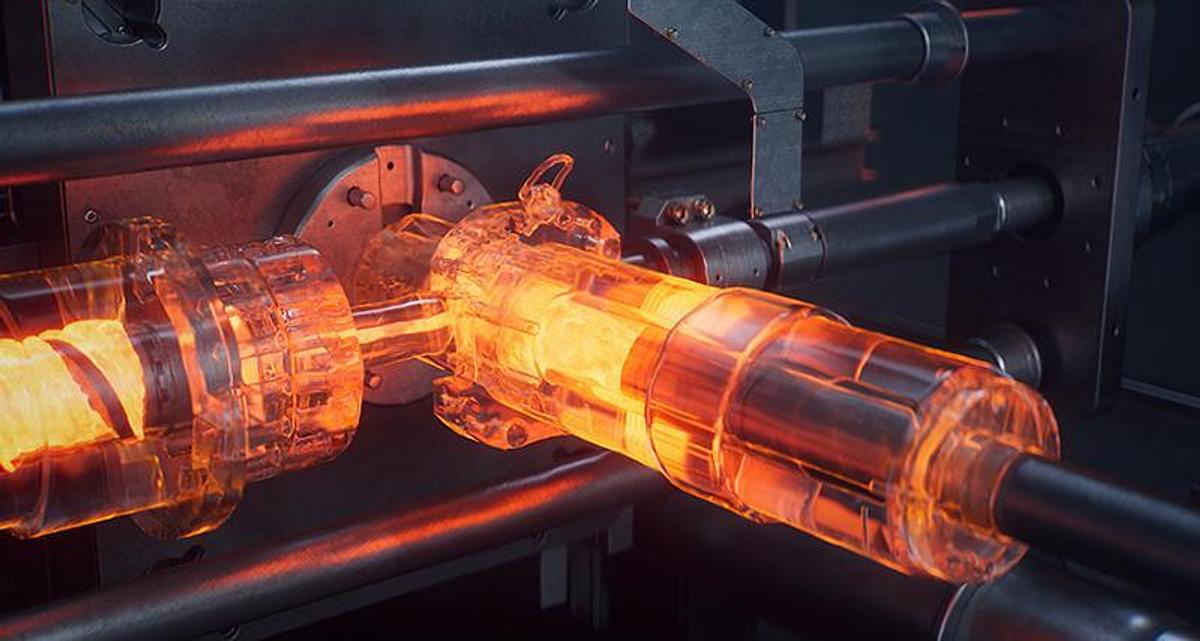

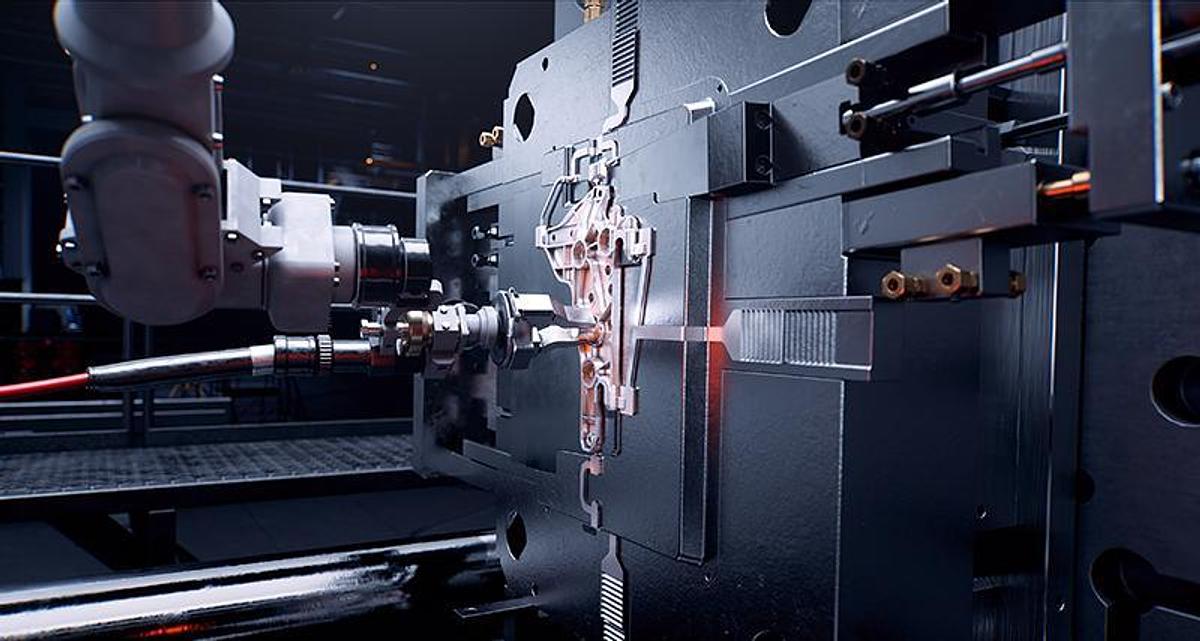

The TPI module can transform any traditional die casting machine into a magnesium alloy semi-solid thixotropic casting process system, and it is completely reversible. This integration enables the casting of larger products under high pressure, has better energy efficiency control, and is more conducive to the production of ultra-thin-wall products at the same time.

Low energy consumption

Compared with traditional cold-chamber die casting, by significantly reducing the working temperature, reducing the magnesium content in the product, and reducing the high power of the system, TPI can significantly reduce energy consumption by up to 50%.

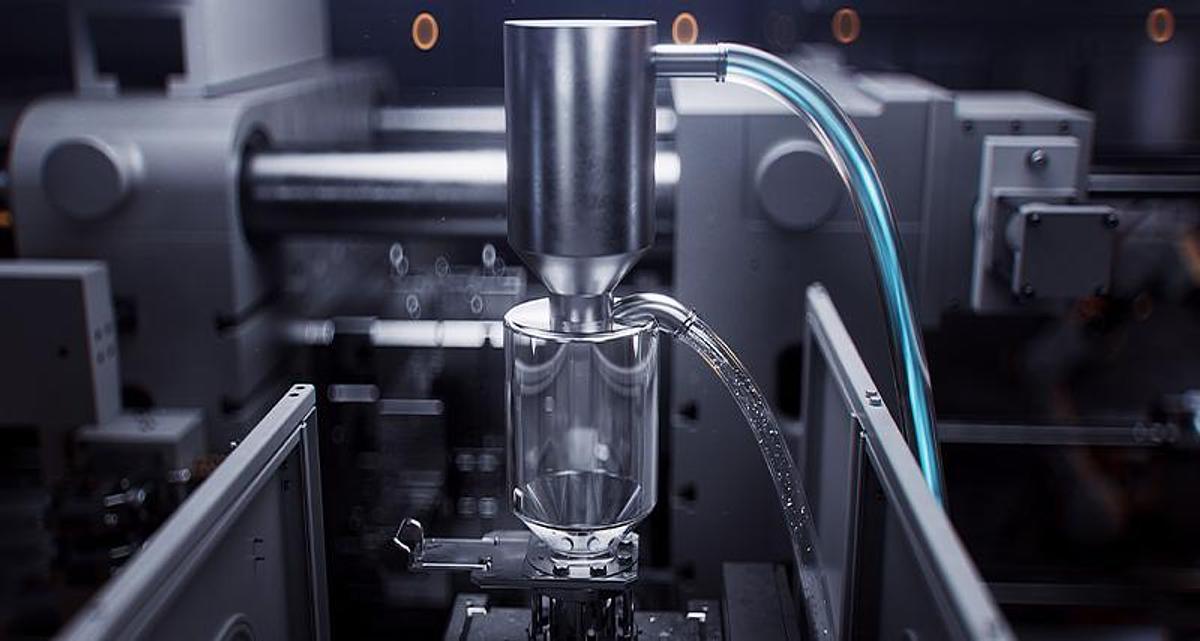

No protective gas required

TPI relies entirely on electrical energy and does not require the use of protective gas, contributing to a more environmentally friendly manufacturing process.

Product optimization

The toughness of semi-solid cast products has increased by 20%, the microstructure is better, the porosity is smaller, and the elongation and tensile strength become higher.

Low cycle time

By simplifying the system, regular maintenance is greatly reduced, thereby achieving smooth and continuous production.

Low cost

If you already have a die casting machine, just purchase the appropriate TPI module to turn it into a semi-solid thixotropic casting machine.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 130-16000 |