D series

Contact us for price

Description

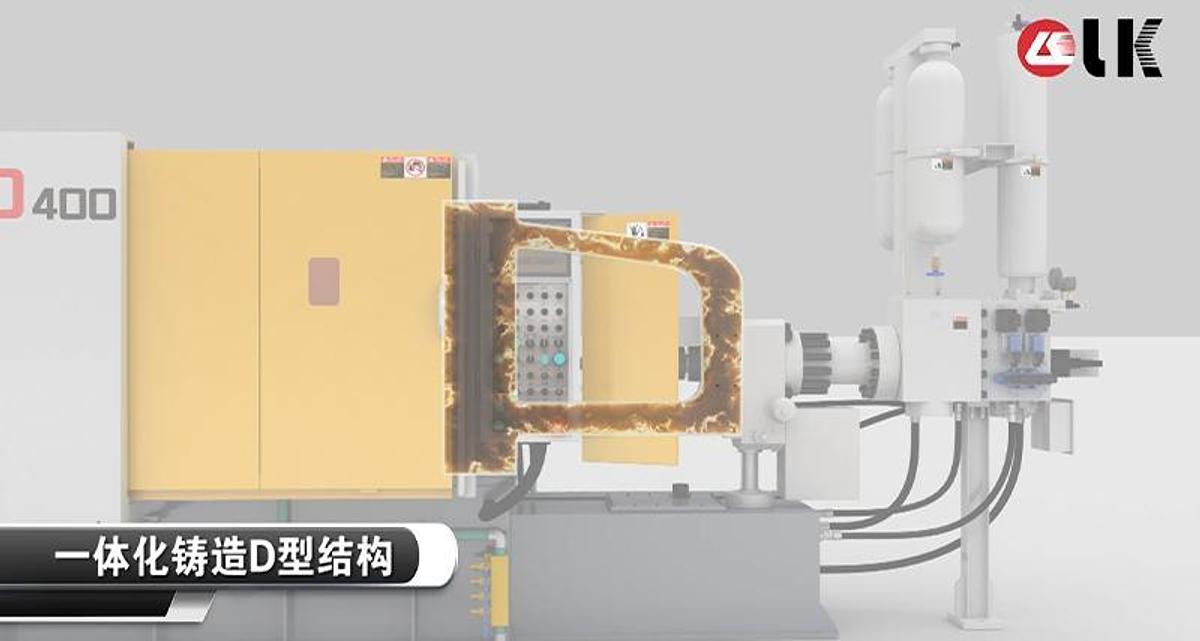

The most distinctive design of the LK D series die casting machines is that its injection mechanism adopts a highly stable and high-strength D-shaped structure design. The high-strength integrated casting D-shaped frame structure has strong rigidity, small platen deformation, balanced force, and effectively avoids stress concentration. The injection process is more stable and reliable. At the same time, the installation holes of the injection cylinder and the shot sleeve are processed at one time, with high coaxiality accuracy, stable and reliable product accuracy, and the injection speed is 9m/s. The "three platens" are reliable in strength through finite element analysis. The standard servo energy-saving system is equipped, with fast die closing speed, high efficiency and strong rigidity.

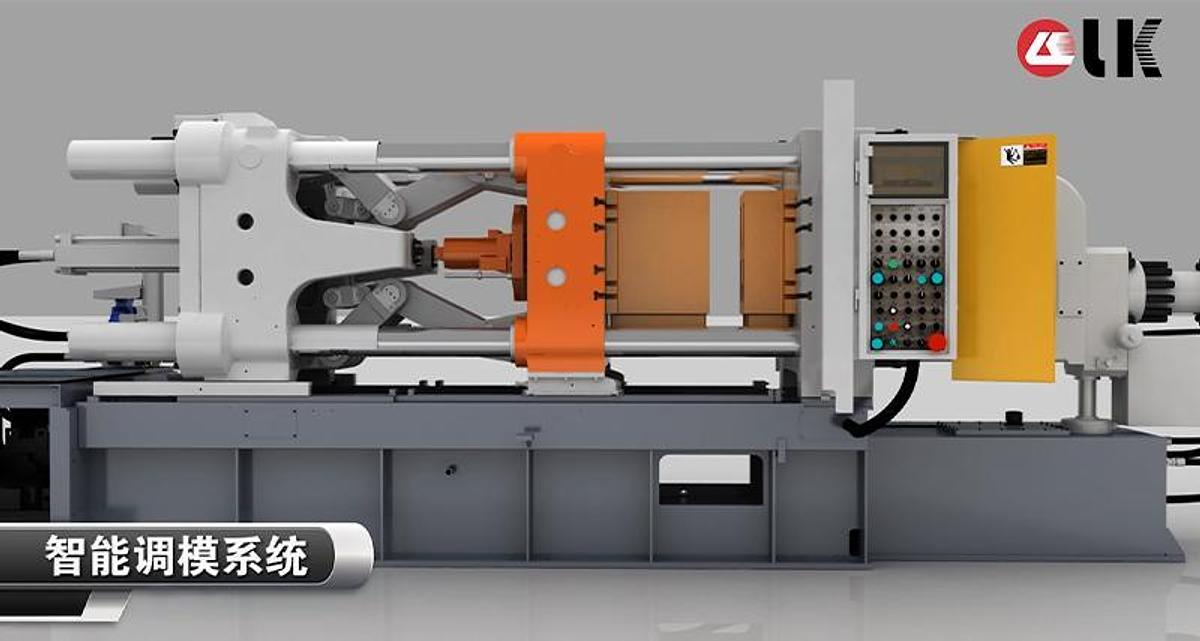

Intelligent Die Height Adjustment

Users only need to set the target clamping force and press two designated buttons simultaneously. The machine can adjust the die thickness according to different dies, shortening the die change time.

User-friendly and Easy to Use

Combined with the principles of ergonomics, the brand-new human-machine interface adopts an integrated design of the operation panel and touchscreen. It can provide production management, fault diagnosis, and screen input data, and is easy to use.Relevant die data can be stored, and users can retrieve the corresponding die production parameters according to actual needs.

Strong and Powerful

It adopts a high-strength integrated casting D-shaped frame structure, with strong rigidity, small platen deformation, balanced force, and effectively avoids stress concentration.

Intelligent Injection

Combined with an excellent hydraulic design system and an accurate control system, full closed-loop control, real-time collection, tracking, and real-time adjustment are carried out to ensure the consistency of the actual speed and the command speed, providing a perfect multi-stage injection control curve.Cooperating with functions such as uniform acceleration at the low-speed end, high-speed filling, and end braking, it provides users with strong injection control capabilities.

Precise and Efficient

The die opening and closing stroke is controlled by a displacement sensor to achieve the accuracy of position control and high repeatability accuracy.The injection stroke is controlled by a non-contact encoder, with high position accuracy, accurate control, and fast response.

Safe and Reliable

The protective cover is added to the machine toggle movement area, providing safer and more reliable protection.The centralized lubrication system ensures the best machine lubrication effect.The crossbeam-free electric safety door can reduce labor and make die change easier.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 160-900 |