IMPRESS-III series

Contact us for price

Description

The third-generation high-performance IMPRESS-III series cold chamber die casting machines are designed based on inheriting the traditional design advantages, rich manufacturing experience and mature application technology of LK die casting machines, incorporating the world's cutting-edge new technologies, new processes and new concepts. It is a new generation of die casting machines with faster speed, more stable performance, energy conservation and environmental protection, featuring the characteristics of a new die-casting era.

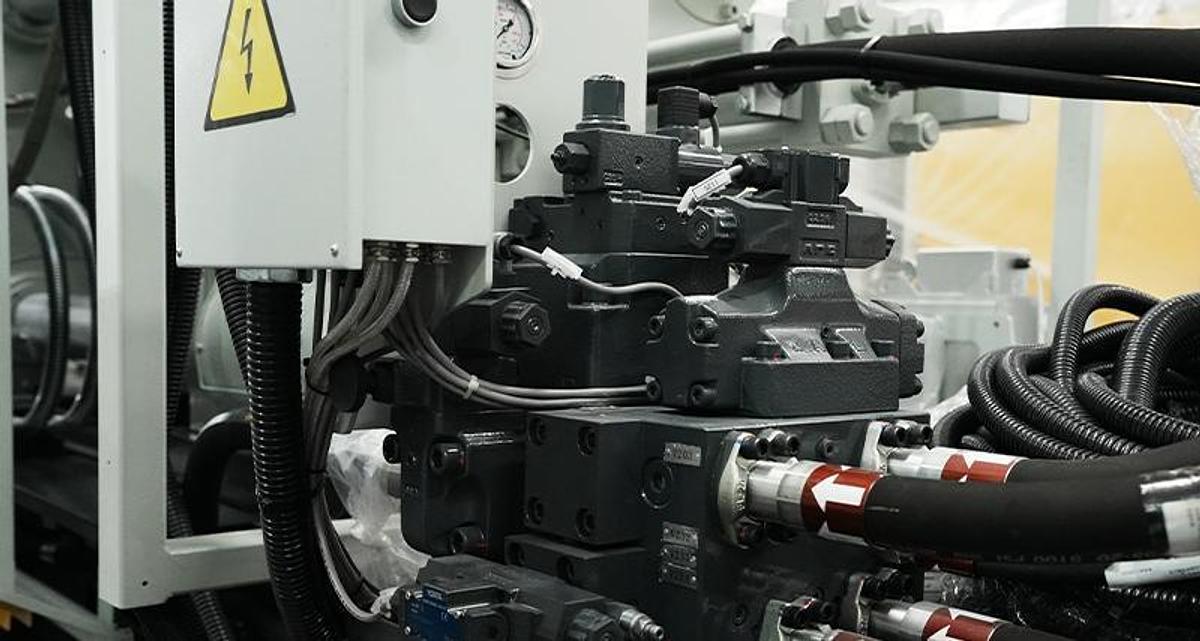

Stable response of the pressure charging system

The injection system has a direct pressure charging structure with a floating piston. The charging response is fast, and the maximum dry cycle speed is ≥ 8m/s. The performance is stable and meets the production requirements of high-precision die-cast parts.

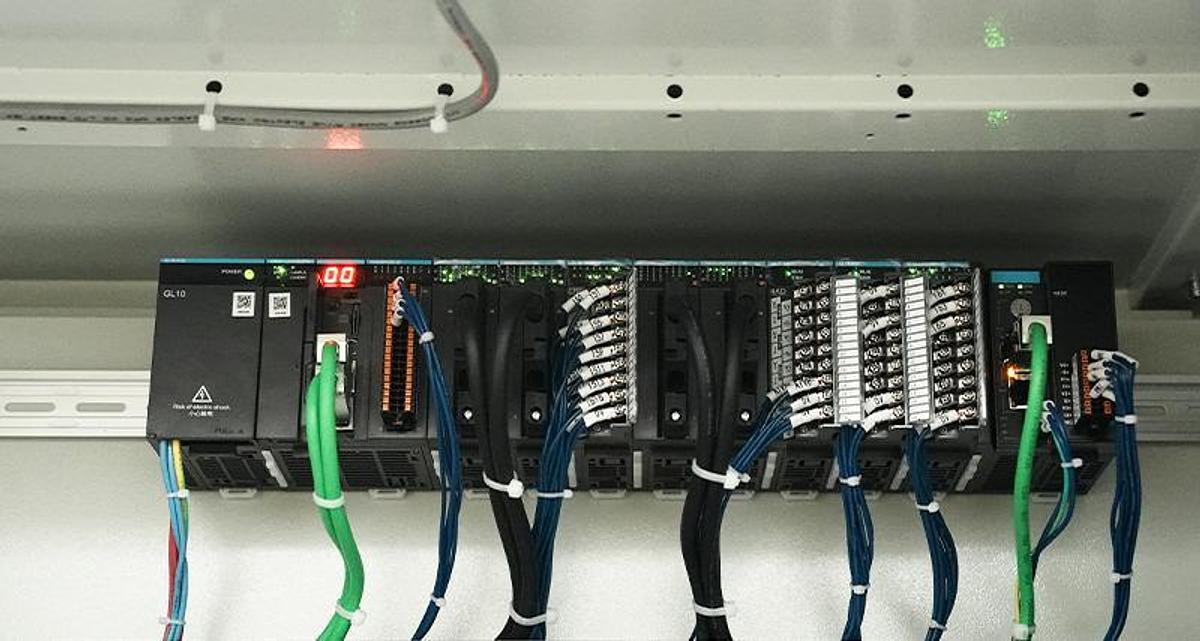

Rapid integration of the control system

The new control system integrates seamlessly with peripheral equipment and has a millisecond-level interruption processing speed.

High repeatability accuracy

The opening and closing die stroke control adopts an position transducer, with precise position control and high repeatability accuracy.

Dual proportional control

The system pressure and system flow are dual-proportionally controlled. Both pressure and flow can be set and adjusted on the touchscreen panel. The unique ultra-fast die locking and opening back pressure control shortens the production cycle and leads to higher production efficiency.

CAE optimized design

The platens adopt a CAE-optimized structural design, with a reasonable stress distribution, high hardness and small deformation, meeting the requirements of precision die casting.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 280-6000 |