IMPRESS-PLUS series

Contact us for price

Description

The IMPRESS-PLUS series die casting machines inherit the advantages of high yield, high efficiency, stability and durability of the IMPRESS-III series die casting machines. At the same time, combined with the product trends of the die casting industry in the new era and the new requirements for die casting processes and die casting production management, it is elaborately created by applying advanced mechanical design, cutting-edge control programs and algorithms, and simulated hydraulic design. It is an intelligent die casting machine.This series of die casting machines integrates intelligent injection control technology, casting quality control technology, efficient die closing transmission technology, intelligent die height adjustment technology and servo energy-saving technology. It can provide a perfect solution for the production of high-precision and high-demanding castings, create value beyond expectations for you and obtain a better return on investment.

Intelligent die casting unit

With a powerful hydraulic system, advanced real-time closed-loop control technology, and flexible and diverse ten-stage injection settings, it can achieve shock-free start-up, multi-stage uniform acceleration, rapid acceleration and deceleration functions. The injection process is extremely stable, meeting the technological requirements of high-quality die casting.

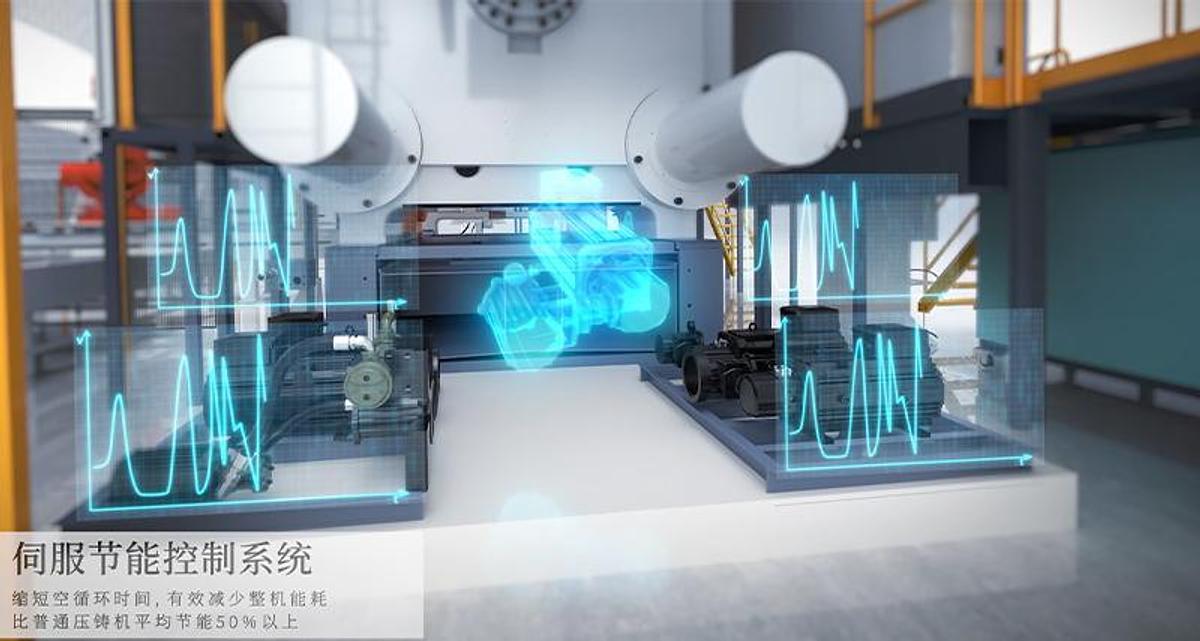

Servo energy-saving control system

It shortens the idle cycle time and effectively reduces the energy consumption of the whole machine. Compared with ordinary die casting machines, the average energy saving is more than 50%.

Platen surface hardening technology

Special platen surface hardening treatment effectively prevents platen surface depression.

Rapid die change system

It meets the rapid replacement of large dies, reduces manpower, completes die replacement within 1 hour, and shortens downtime.

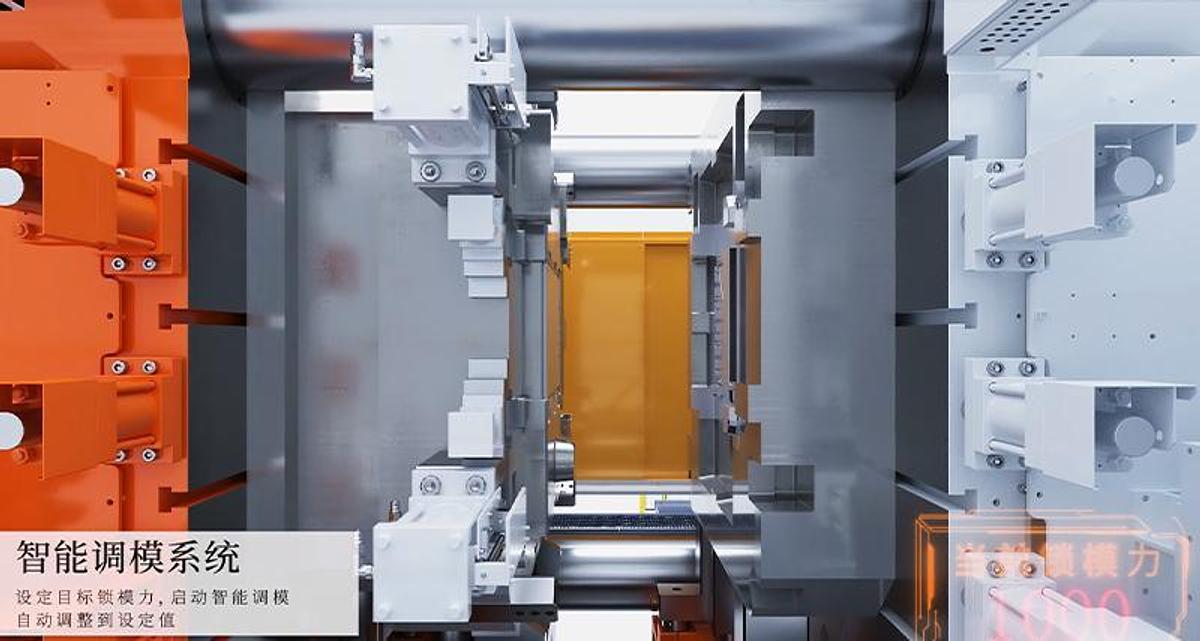

Intelligent die height adjustment system

Set the target clamping force, and start the intelligent die height adjustment to automatically adjust to the set value.

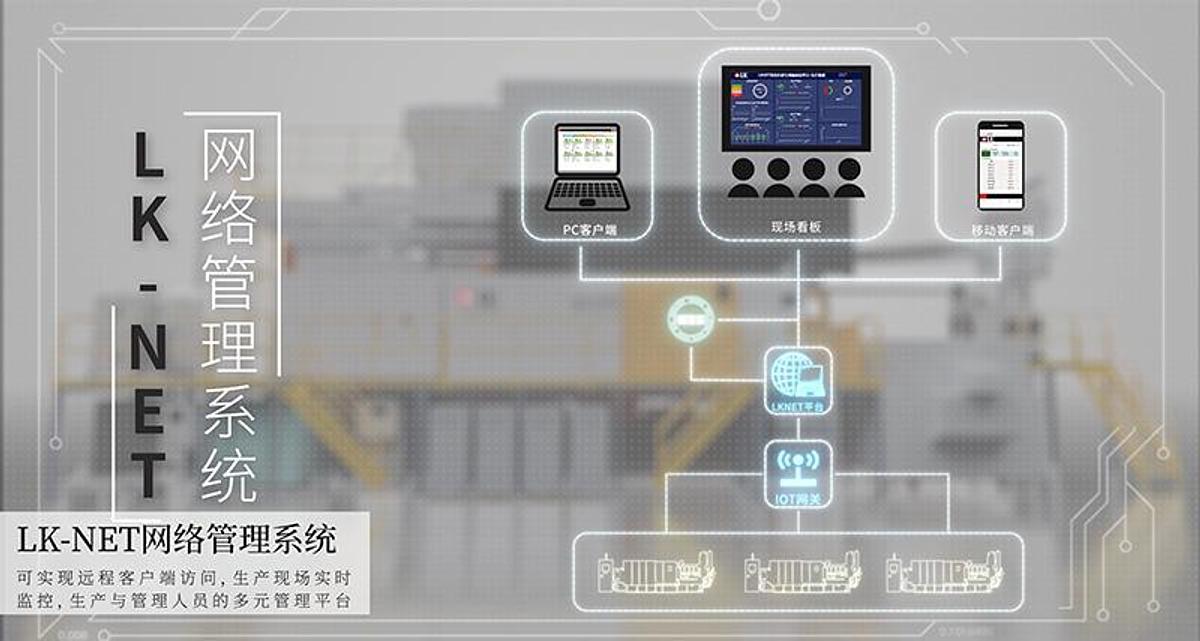

LK-NET network management system

It can realize remote client access, real-time monitoring of the production site, and a multi-element management platform for production and management personnel.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 6000-9000 |