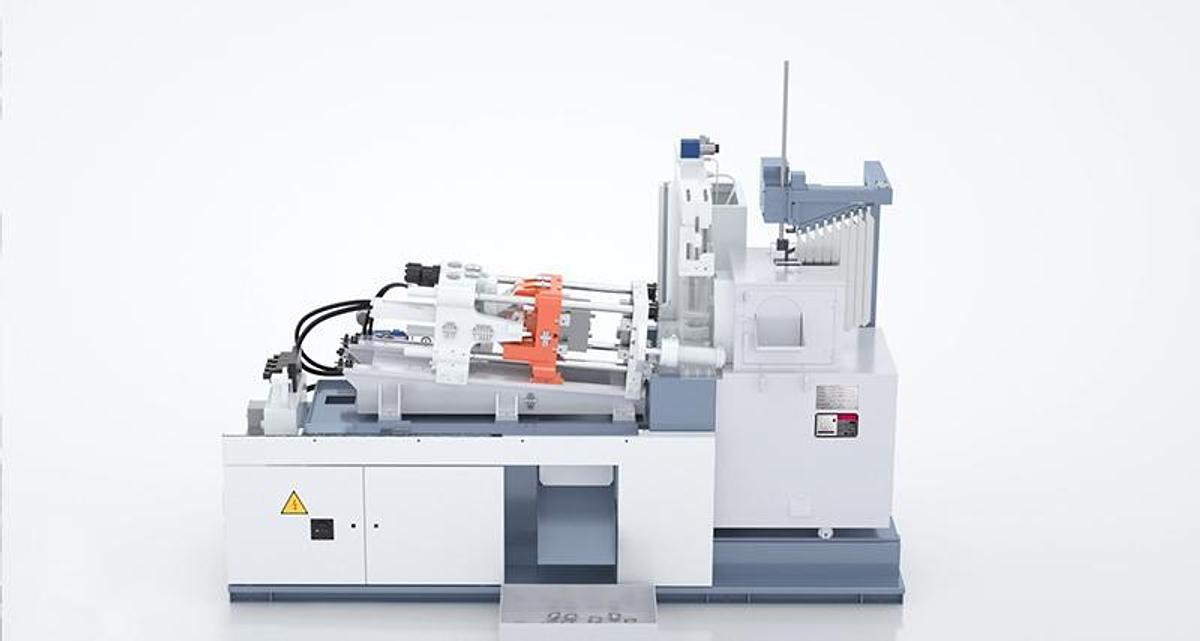

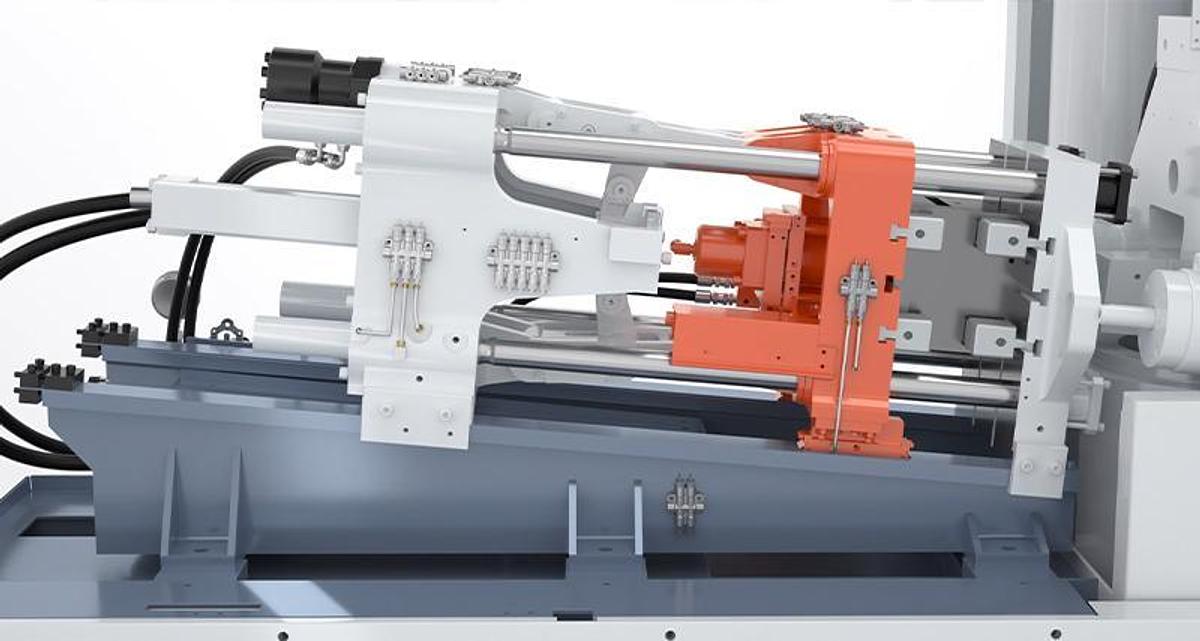

AVIS-II series

Contact us for price

Description

Since the launch of the first AVIS machine in 1994, the hot chamber machine AVIS has become a representative of professional, high-quality and high-efficiency die casting machines. The newly launched AVIS-II series has a higher level of standard equipment and uses the latest servo energy-saving technology at present, with significant energy-saving effects. Currently, the AVIS-II series is a world-class hot chamber die casting machine.

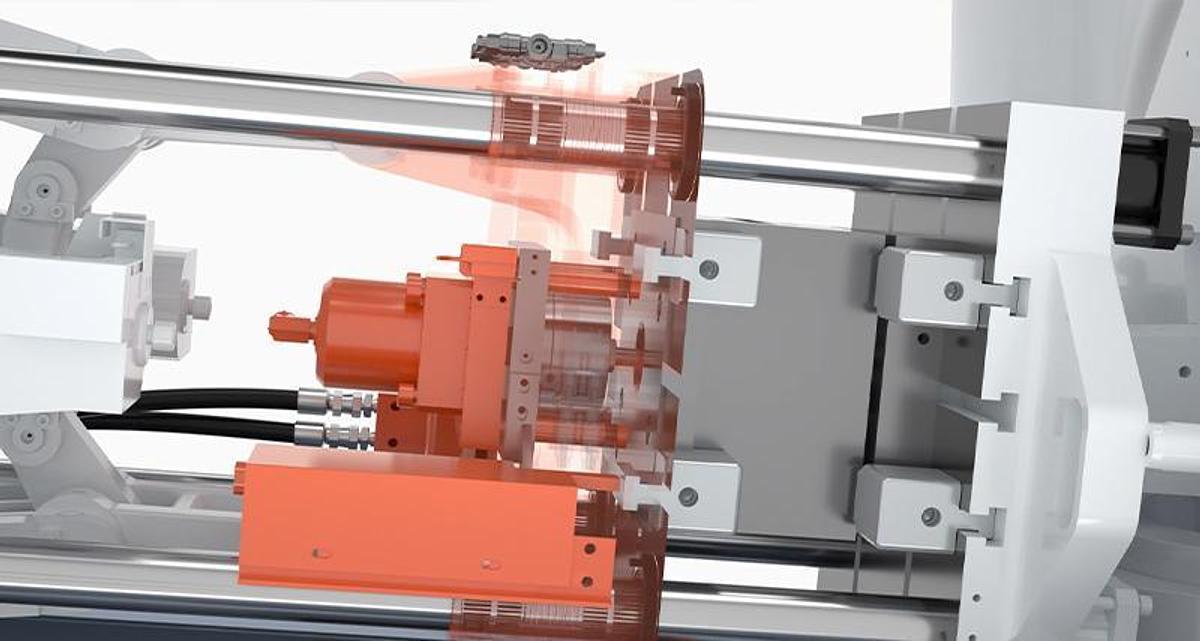

Rapid die change system

One-key clamping function, shortening the die change time.Reducing the workload and improving the work efficiency.Improving the working environment and enhancing the operation safety.

Control system

Adopting a high-grade world-renowned brand PLC, equipped with a large color touchscreen, reliable performance, intuitive operation and easy to use.

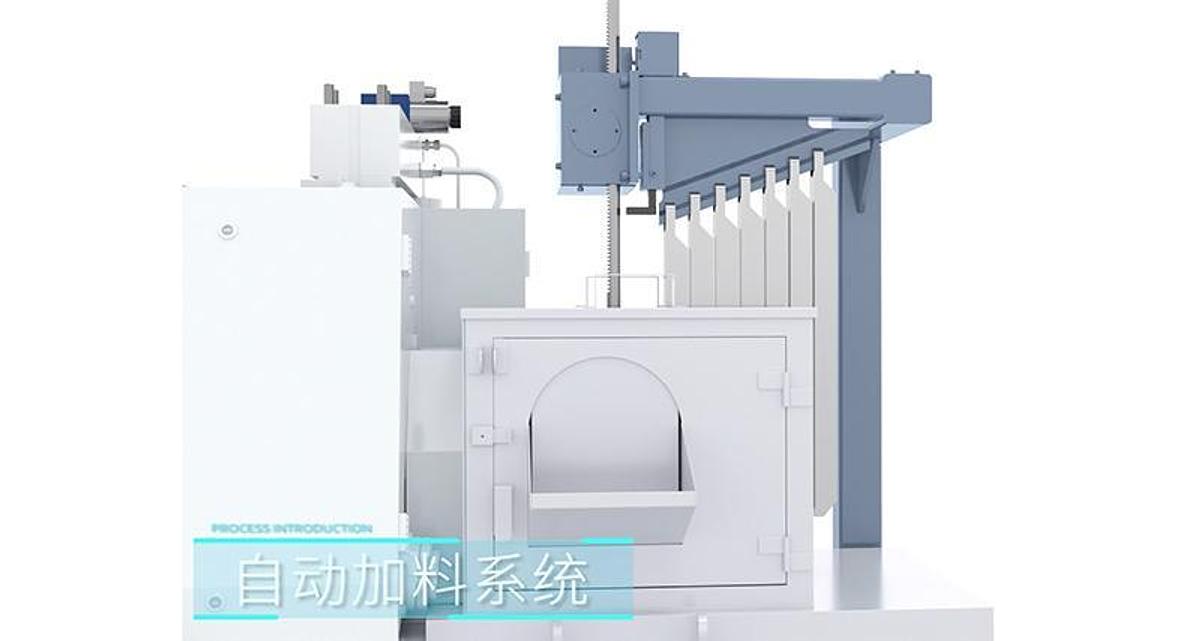

Automatic feeding system

The ingots are automatically put into the furnace.Eliminating manual operation.Making the melt temperature more stable.Maintaining the accuracy of each casting.

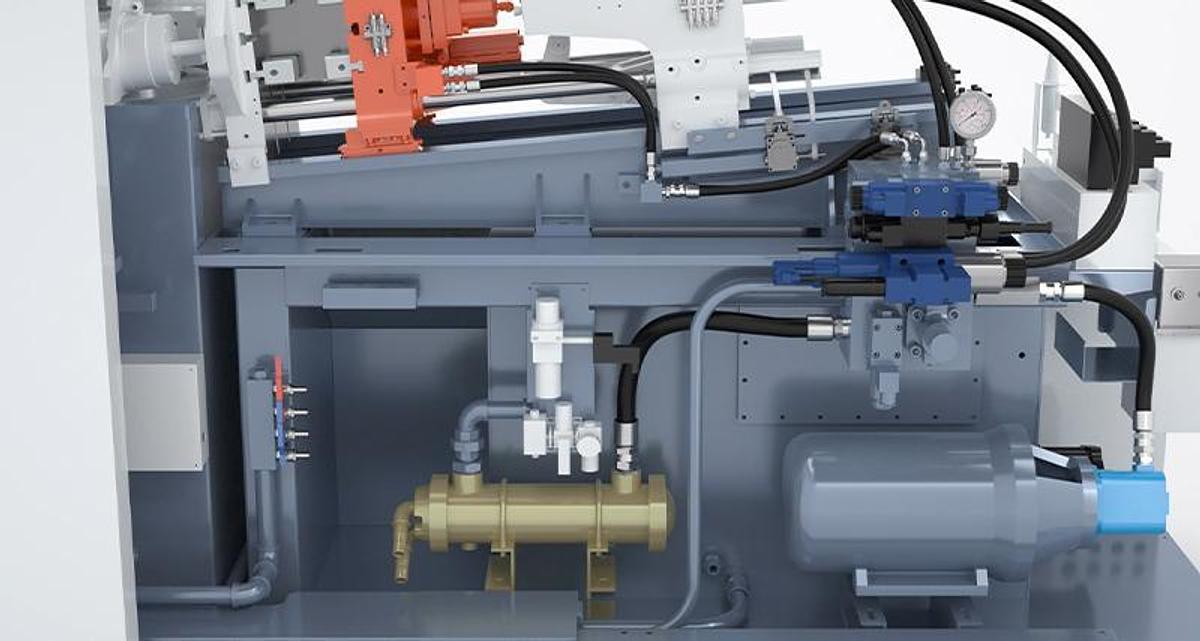

Adopting the world-famous brand servo motor pump system

Energy conservation and environmental protection, with an average energy saving of 30%-60%.Lower noise.Reduction of carbon dioxide emissions.Reduction of cooling water consumption.Closed-loop pressure control, fast response time.Longer service life of the pump.

New fully enclosed sheet metal structure

Novel and beautiful, meeting the requirements of safety standards and ensuring the safety of operators.The operating platform is ergonomically designed, people-oriented.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 30-400 |