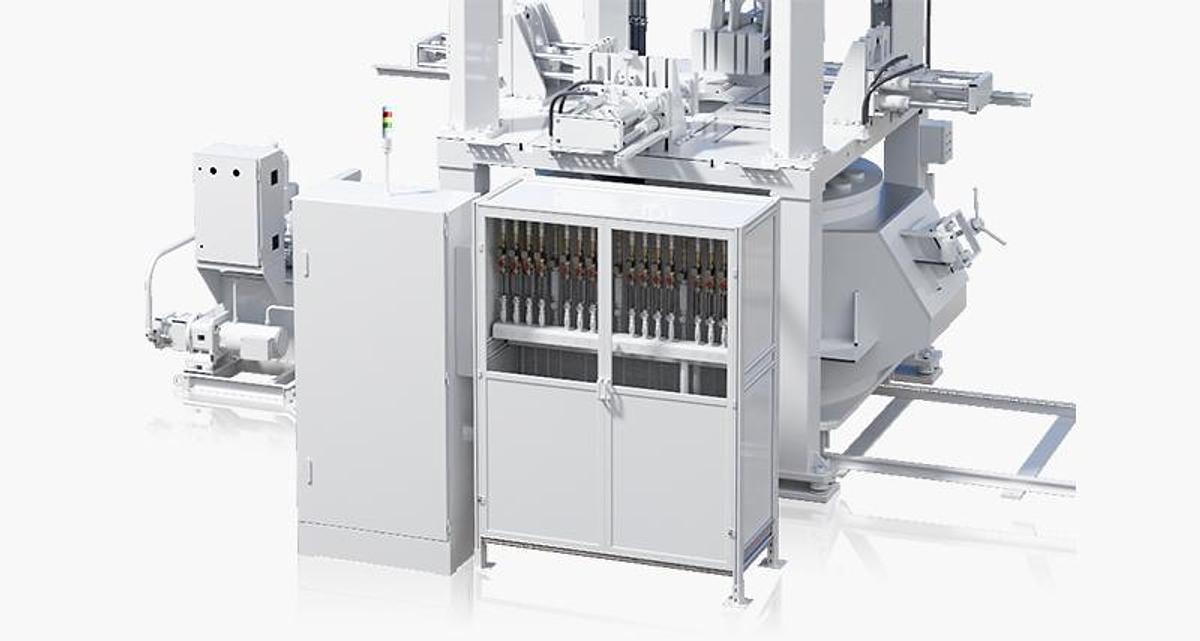

LPC series

Contact us for price

Description

It is a series of special casting equipment by LK, characterized by a simple and beautiful equipment structure and high overall rigidity. It is widely used in EV chassis castings such as subframes, steering knuckles, wheels and other products.

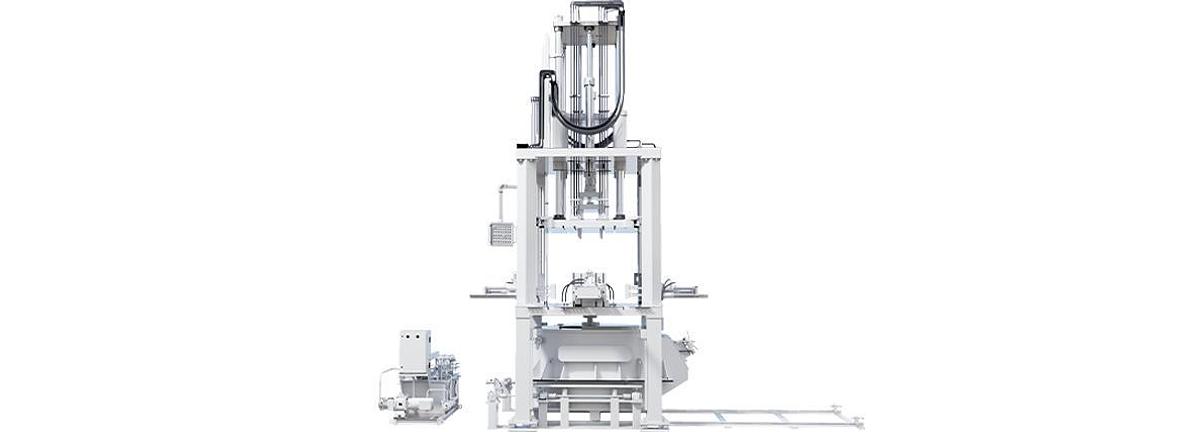

High precision control system, more intelligent, convenient and precise

Adopting PID automatic adjustment function, digital valve island technology and special pressure detection system to form closed-loop control. The pressure of molten aluminum is controlled in 10 stages by electronic proportional valve, and the control accuracy of holding pressure is ≤ ±1mbar.

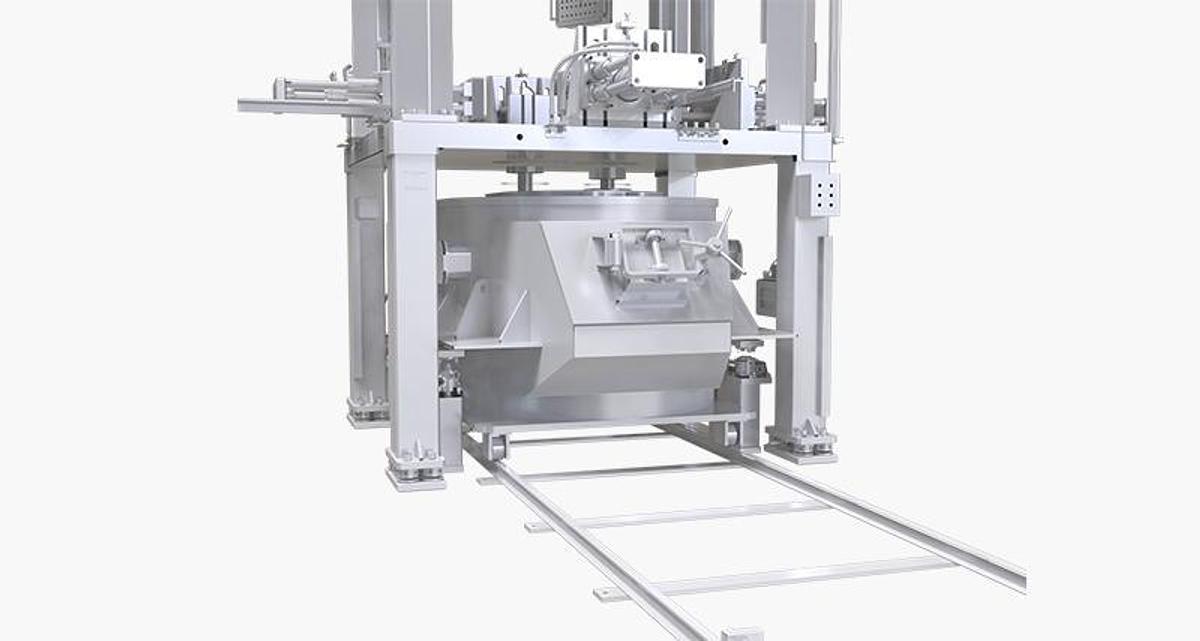

High-precision filling system, more stable, controllable and efficient

The filling of molten aluminum has the function of automatic pressure compensation. The repetitive error of filling process parameters is less than 1%. The filling and pressurization pressure curves of each shot are consistent.

High-intelligent operating system, simpler, more comfortable and reliable

Adopting Siemens S7-1500 PLC, LK patent distributed IO control with nanosecond-level computing speed, industrial control version closed-loop control system with high computing power, nanosecond-level computing speed, and human-machine control interface VI design.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 500-4000 |