E-PRESS series

Contact us for price

Description

E-PRESS is a cold-chamber die casting machine newly developed by LK over a period of two years. It has cracked multiple key technologies, met customer demands and industry development, and is positioned at the high end.This series of die casting machines adopts all-electric die locking technology. The high-precision and high-speed all-electric die locking system uses high-frequency response servo motors to drive the die closing mechanism. This is the first case in China to apply all-electric die locking technology to die casting machines. It can produce products such as aluminum alloys, magnesium alloys, copper, and zinc alloys.

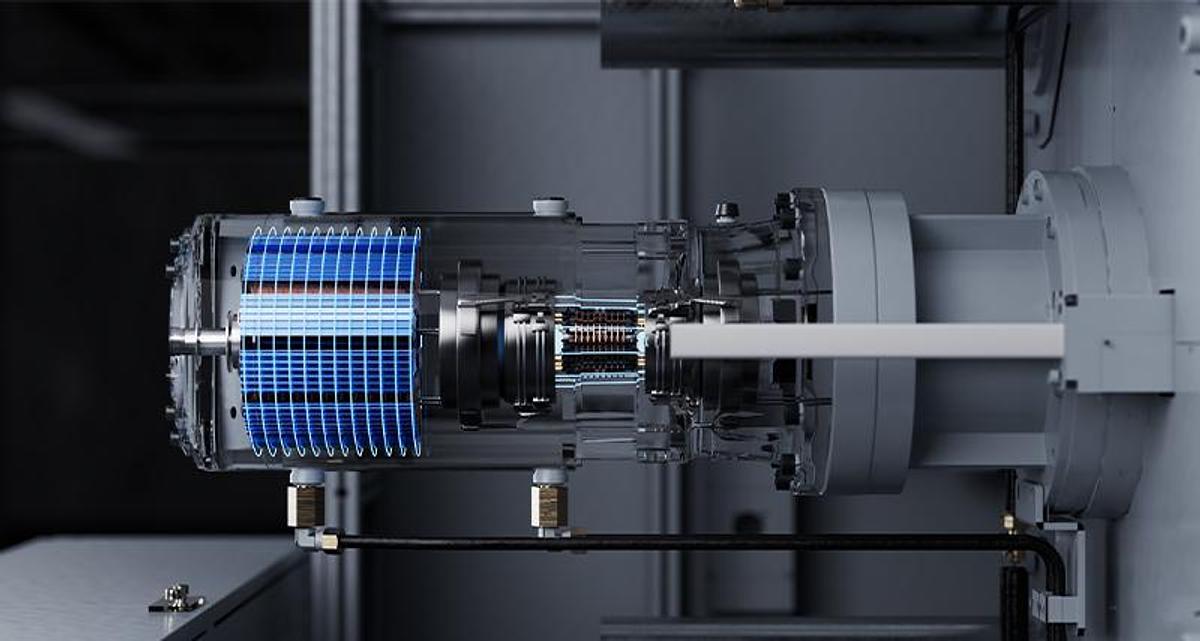

High-speed and high-precision all-electric die locking technology

The displacement control accuracy of die locking and opening is 0.01mm.The repeat accuracy of the die opening position is ≤ 0.2mm.The die opening and closing cycle is shortened, and the production efficiency is increased by 10%.

High-response industrial computer control system

High-response central processing unit with a control cycle of 0.25ms.Dual closed-loop real-time control technology for pressure and speed.High-precision speed and pressure trajectory tracking technology.Intelligent adaptive and robust control algorithm.High-speed intelligent end braking technology.Real-time bus distributed control system.Intelligent die locking and opening control technology.Euromap humanized graphical interface.

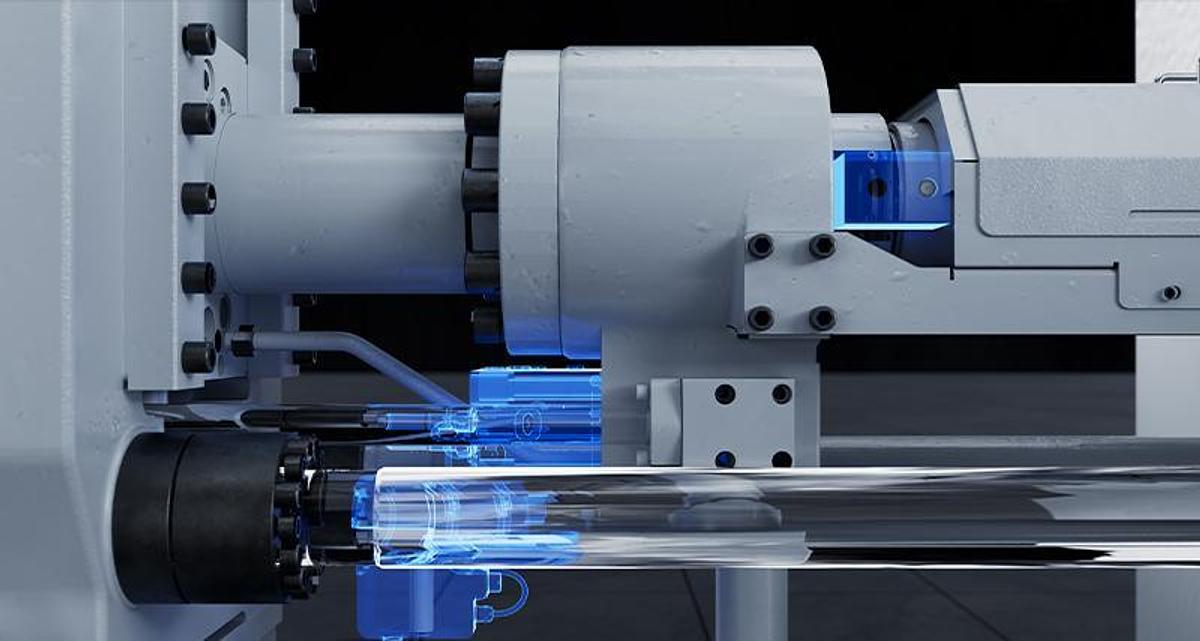

High-performance and high-precision injection system

Adopt a high-dynamic and high-precision injection system.The injection pressure is 210 bar.Adopt intelligent dual closed-loop real-time control technology.

Specifications

| Manufacturer | LK |

| Condition | New |