DREAMPRESS series

Contact us for price

Description

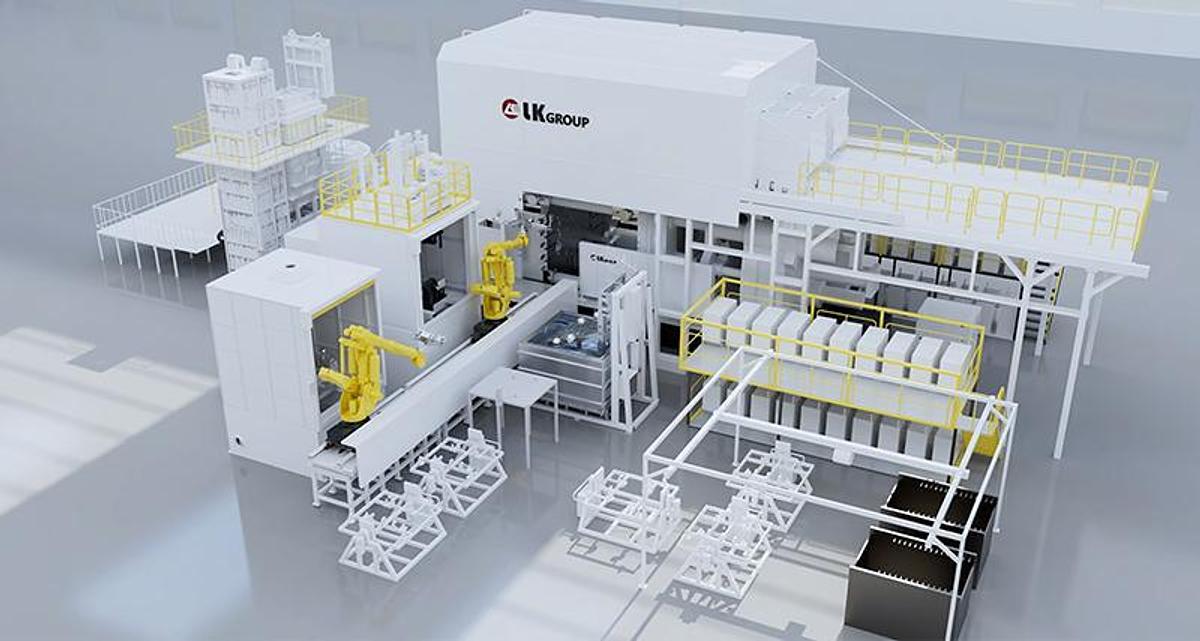

The DREAMPRESS series of giga intelligent die casting units have transformed from single-function and multi-process die casting to multi-functional integrated die casting, achieving one-time forming of large automotive structural parts. This reduces the number of production lines and assembly processes, saves costs such as labor, space and equipment, compresses the production cycle, improves production efficiency, simplifies complexity and makes automotive manufacturing simpler.The integrated die casting technology of the LK DREAMPRESS series uses "die casting units" to replace the traditional "stamping lines + welding lines", simplifies complexity and drives an unprecedented change in car body manufacturing processes in a century. Die casting units have become the core equipment for vehicle manufacturing.

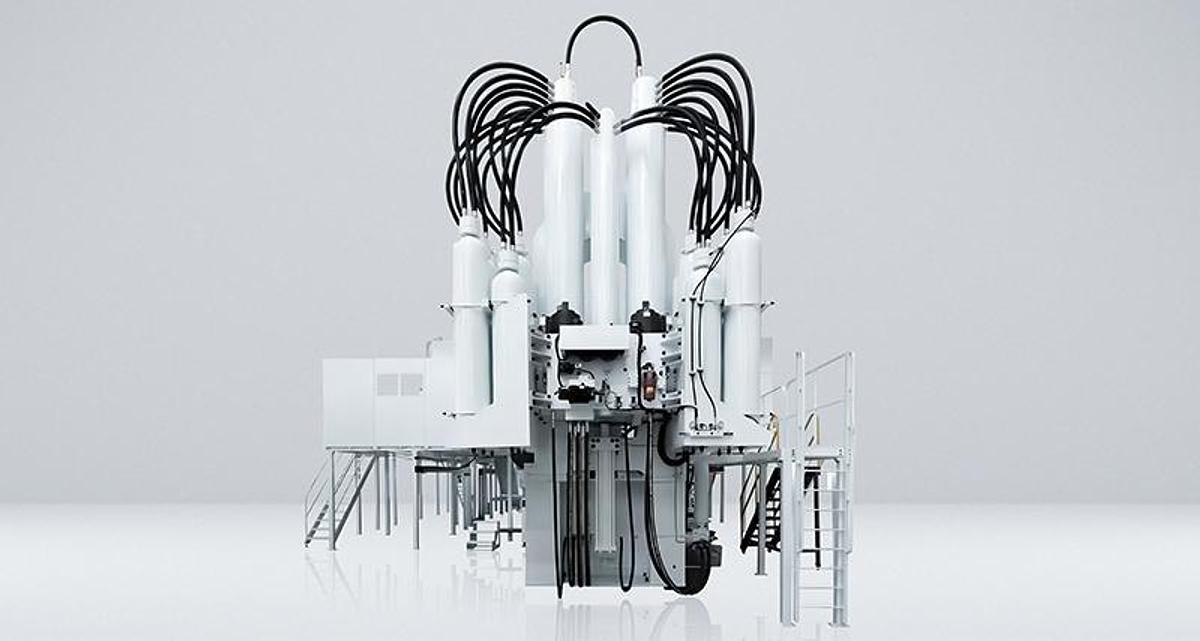

High Response · Hydraulic Design

Brand-new high-response hydraulic design.Real-time monitoring of injection status.Precise control reflects superb injection function.Integrated injection unit design, smooth hydraulic oil flow, few hydraulic components, low failure rate and easy maintenance.

Intelligent Networking · Die Casting Unit

Overall solution for die casting units.Maximally optimize the cycle time of each process.Precisely control the thermal balance of the die.Improve production efficiency.Intelligent diagnosis.

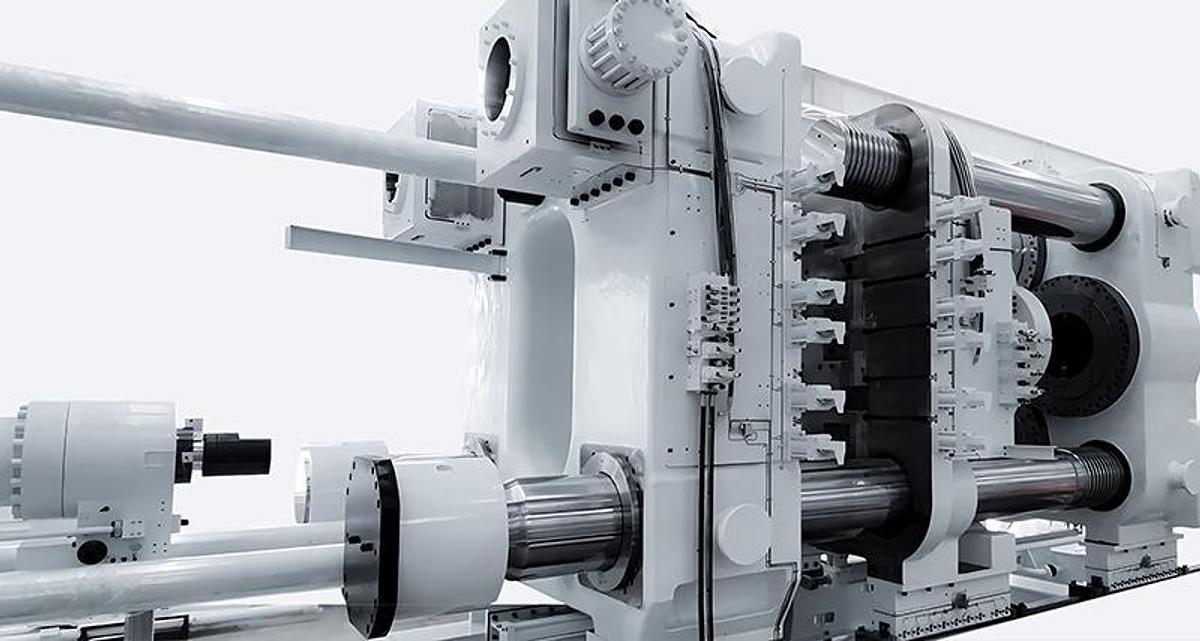

High-Strength · Locking Unit Design

The stressed area of the platen is separated from the die fitting area, and the die is not affected by the deformation of the platens.The movement of the moving platen is supported by linear guides, with sensitive and rapid response and low motion loss.Constant output of clamping force, customizable clamping force.Fast die opening and closing speed, smooth movement.Few moving parts.

Specifications

| Manufacturer | LK |

| Condition | New |

| Tonnage | 9000-16000 |