MT-900

Contact us for price

Description

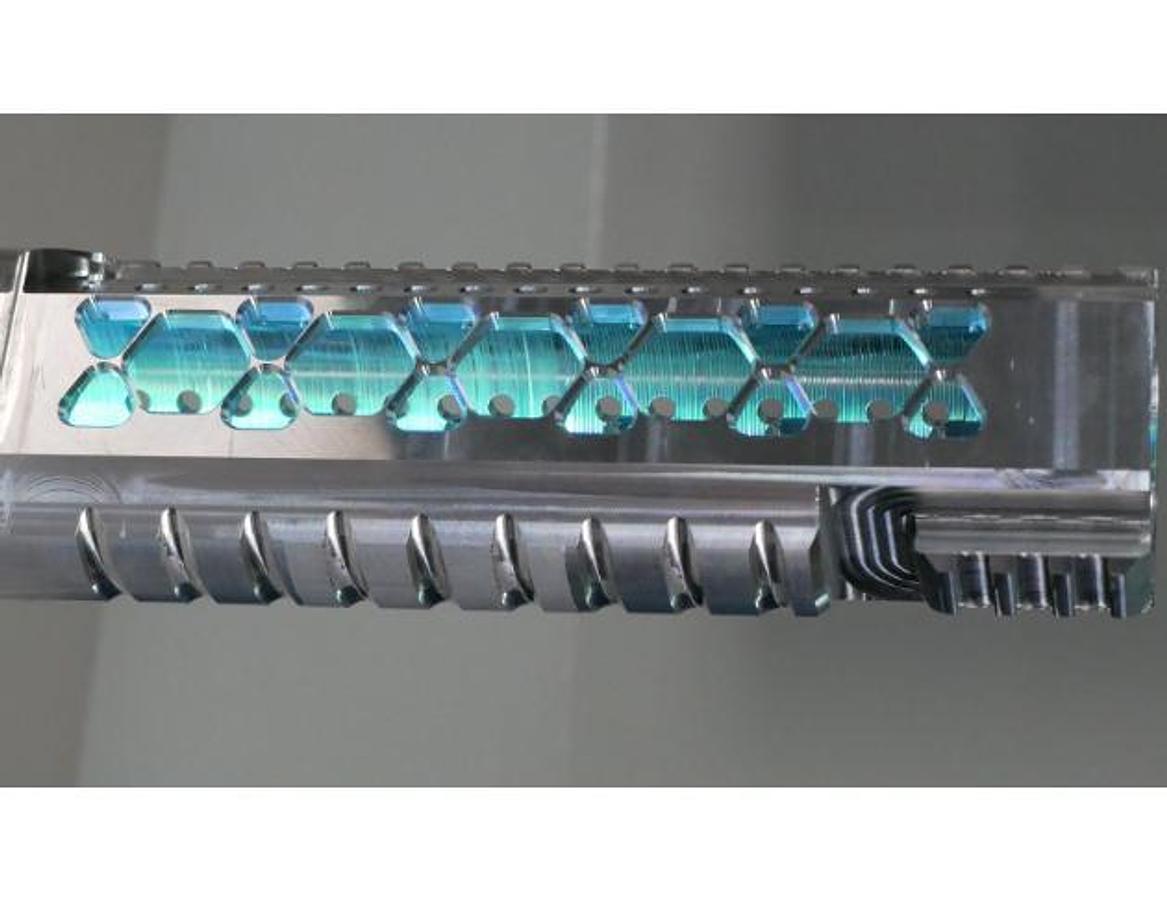

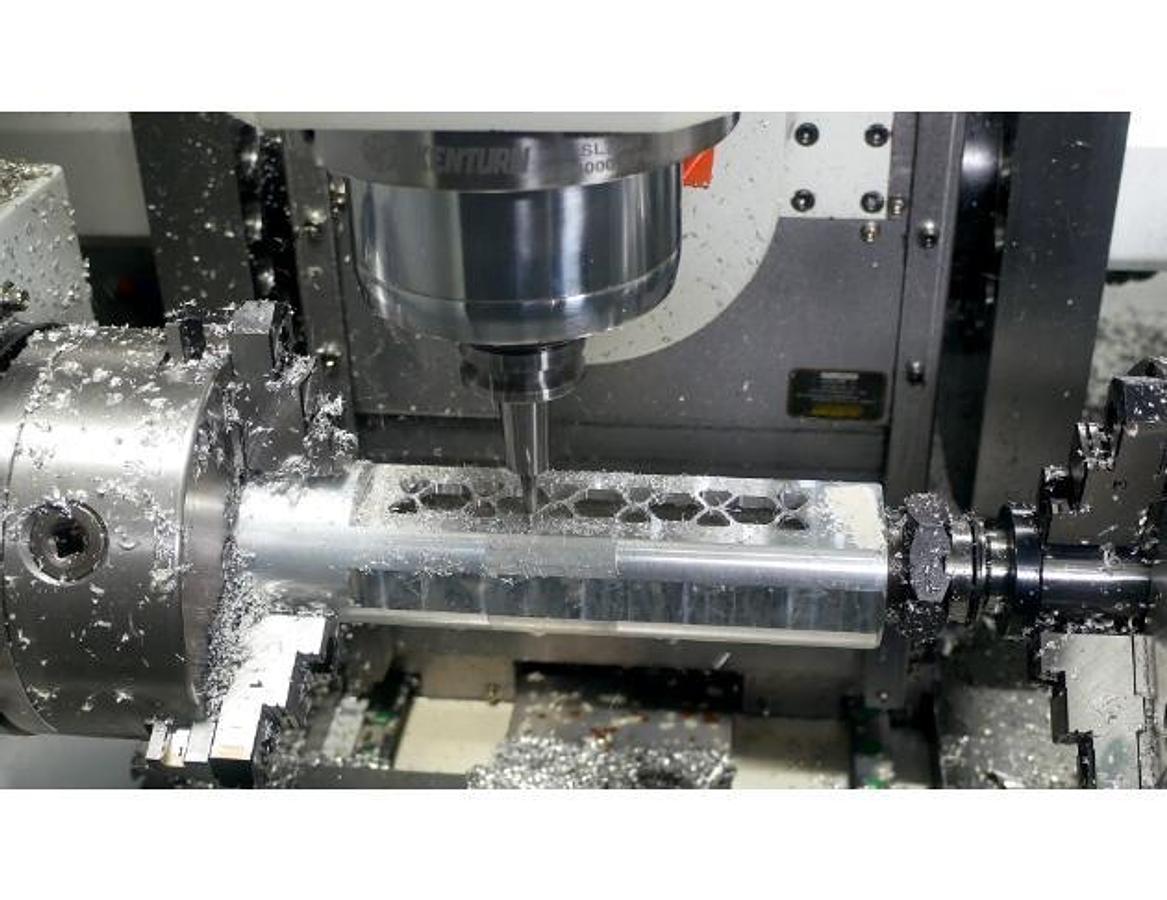

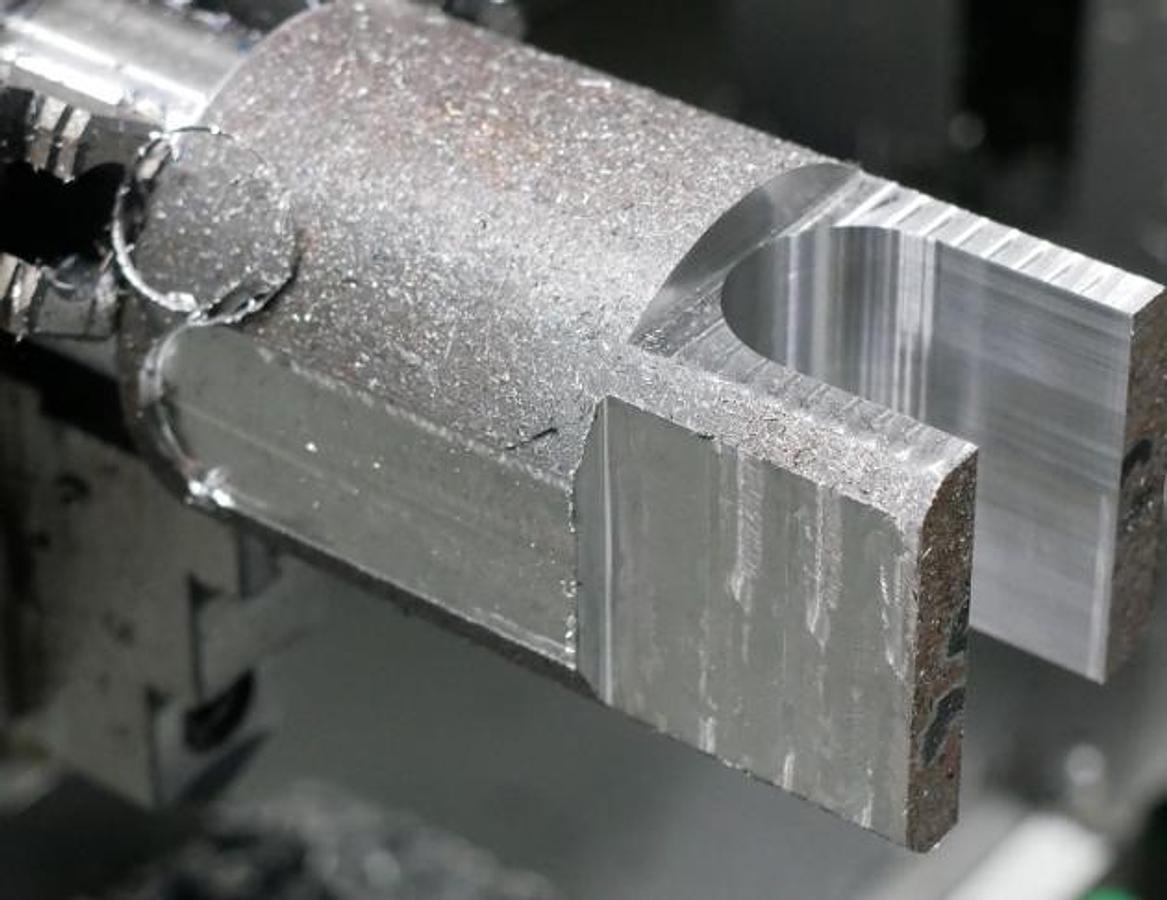

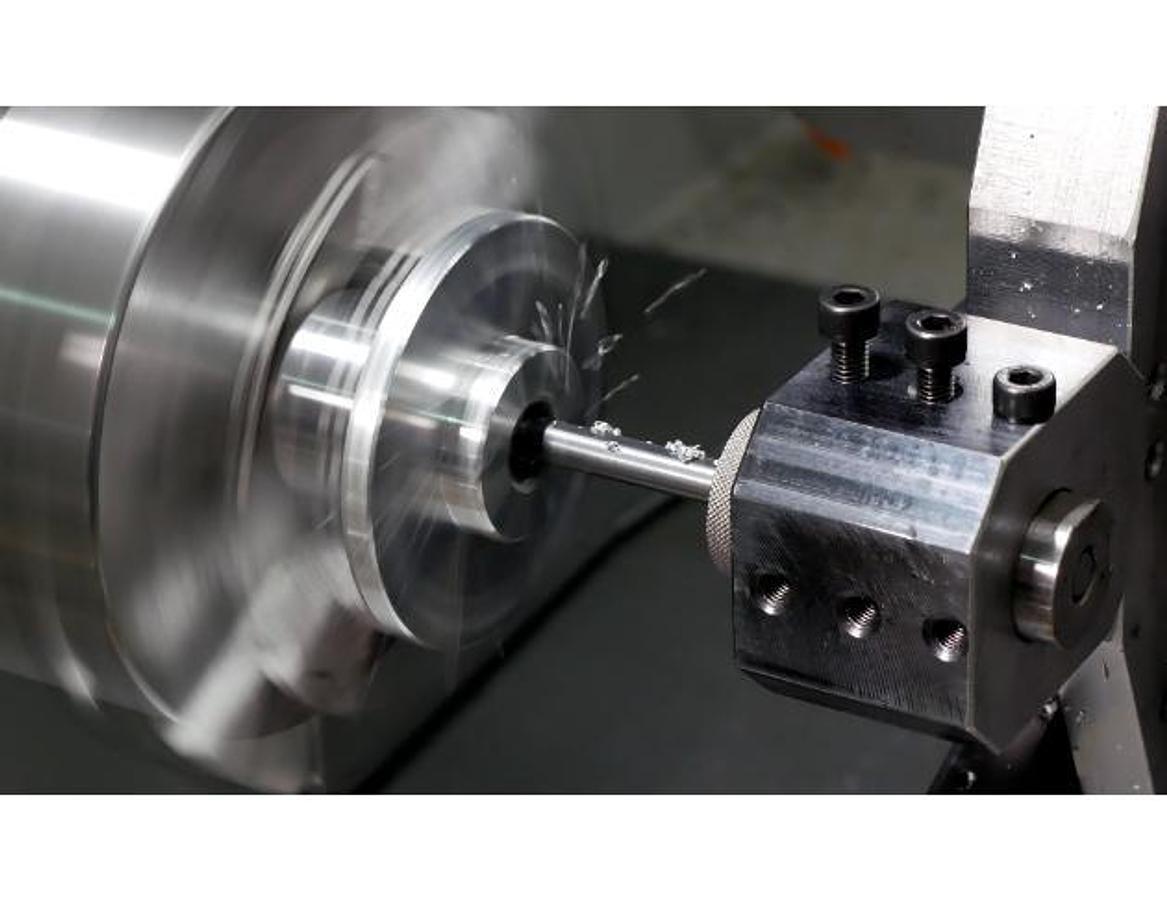

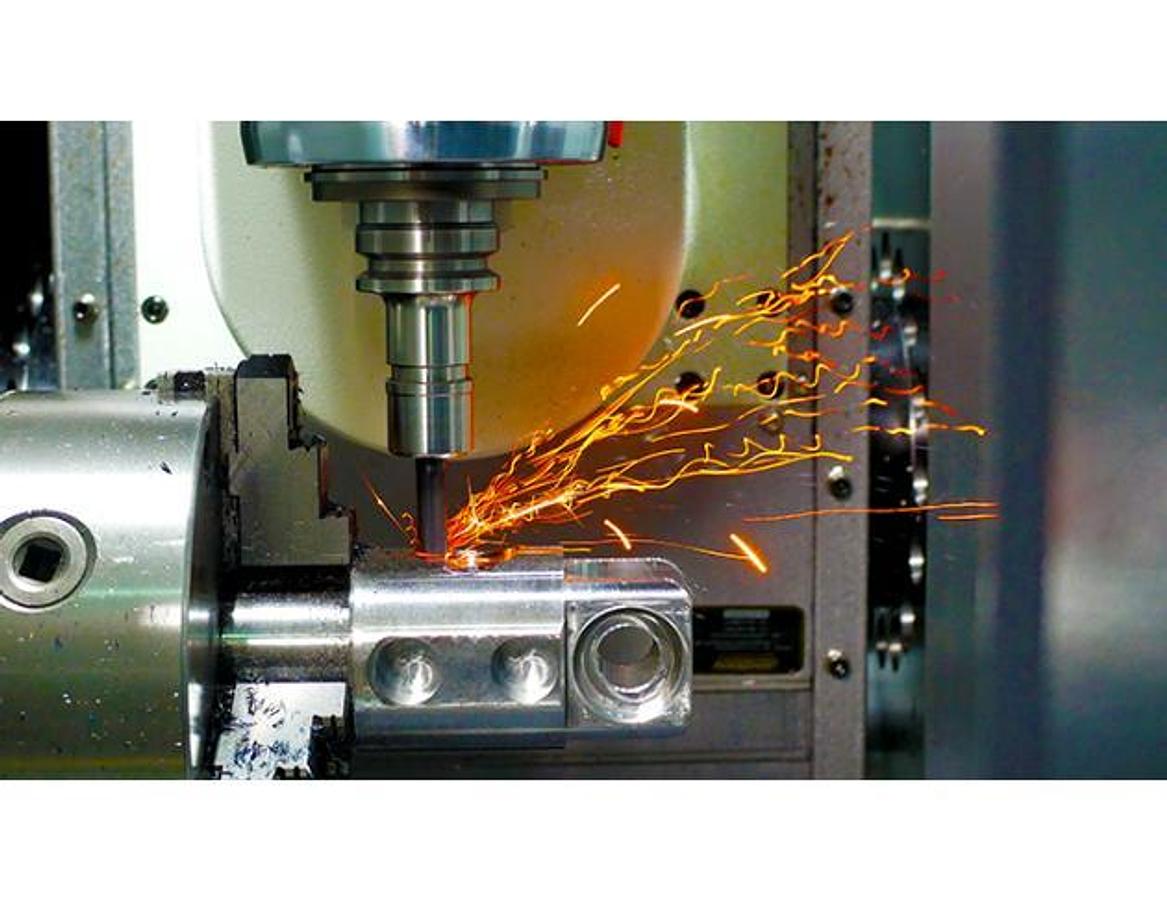

The MT-900 is a multi-axis mill-turn center designed to consolidate turning, milling, drilling, tapping, and multi-face machining into a single setup. With X/Y/Z/W linear axes combined with A, B, C1, and C2 rotary axes, the MT-900 offers flexible machining capability for a wide range of medium-complexity parts. Its configuration is similar to the MT-210, but with a longer machining length to accommodate extended workpieces and larger process requirements.

The machine features a 3,000-rpm main spindle (A2-5) with a 6-inch chuck, suitable for general turning applications. The built-in BBT-30 milling spindle reaches up to 24,000 rpm, supporting efficient light-to-medium milling operations. The B-axis provides ±105° of rotation with 1,080 N-m of torque, enabling multi-angle machining and improved process flexibility. Dual C-axes with 0.001° indexing capability support synchronized operations between the main and sub-spindle.

With rapid traverse speeds up to 30 m/min and a 24-tool magazine, the MT-900 enhances production efficiency in multi-process workflows. The left and right servo turrets (11 stations each) further expand tooling capacity and enable smooth transitions between cutting operations.

The MT-900 is well-suited for general industrial components, automotive parts, mechanical assemblies, and medium-complexity turned-milled work that benefits from process consolidation or reduced handling. By allowing multiple operations to be completed in one setup, the MT-900 improves throughput, consistency, and overall workflow efficiency—especially for users requiring slightly longer machining capability compared to the MT-210.

Specifications

| Manufacturer | Ingenious Machinery |

| Condition | New |

| ITEM | UNIT MT-900 |

| Swing over bed | mm Φ500 |

| Max. machiing diameter | mm Φ300 |

| Max. machining length | mm 922 |

| X/Y/Z/W-axis | mm ±150 / 420 / 900 / 968 |

| B / C1/C2/a-axis | ° ±105° / 360°/ 360° / 360° |

| Speed | rpm 3,000 (belt-drive) |

| Spindle nose | A2-5 |

| Spindle bore dia. / Draw bar dia. | mm Φ56 / Φ45 |

| Front bearing inner dia. | mm Φ80 |

| Chuck size | inch 6″ |

| Tool shank type | BBT-30 |

| Max. spindle speed | rpm 24,000 (Built-in) |

| Max. spindle torque | Nm 7.8 |

| A-axis index | arcmin 1 |

| Rotary angle | ° 360 |

| Max. speed | rpm 3,000 |

| Max. torque | Nm 49 |

| Repeatability accuracy | arcmin ±0.1 |

| B-axis index | arcmin 1 |

| C-axis index | arcmin 1 |

| X/Y/Z/W-axis rapid traverse | m/min 24 / 30 / 24 / 24 |

| Tool capacity | pcs 11 |

| Max. tool diameter / length | mm Ø80 x 150 |

| Max. tool weight | kg 3 |

| Tool change time | sec 4.8 |

| Type | Servo |

| Squre tool shank | mm 20 x 20 |

| Boring bar shank | mm Ø32 |

| Main-spindle | kw 7 |

| Sub-spindle | kw 3 |

| Milling-spindle | kw 10 |

| X/Y/Z/B/W-axis | kw 1 x 5pcs |

| Tool magazine | kw 1 |

| Turret (Left / Right) | kw 0.75 x 2pcs |

| Hydraulic oil pump | kw 0.75 |

| Coolant pump | kw 0.85 |

| Requirement | KVA 380-415 / 220V 30KVA |

| L x W X H | cm 394 x 230 x 254 |

| Net weight | kgs 5,000 |

| Gross weight | kgs 5,284 |