MT-540

Contact us for price

Description

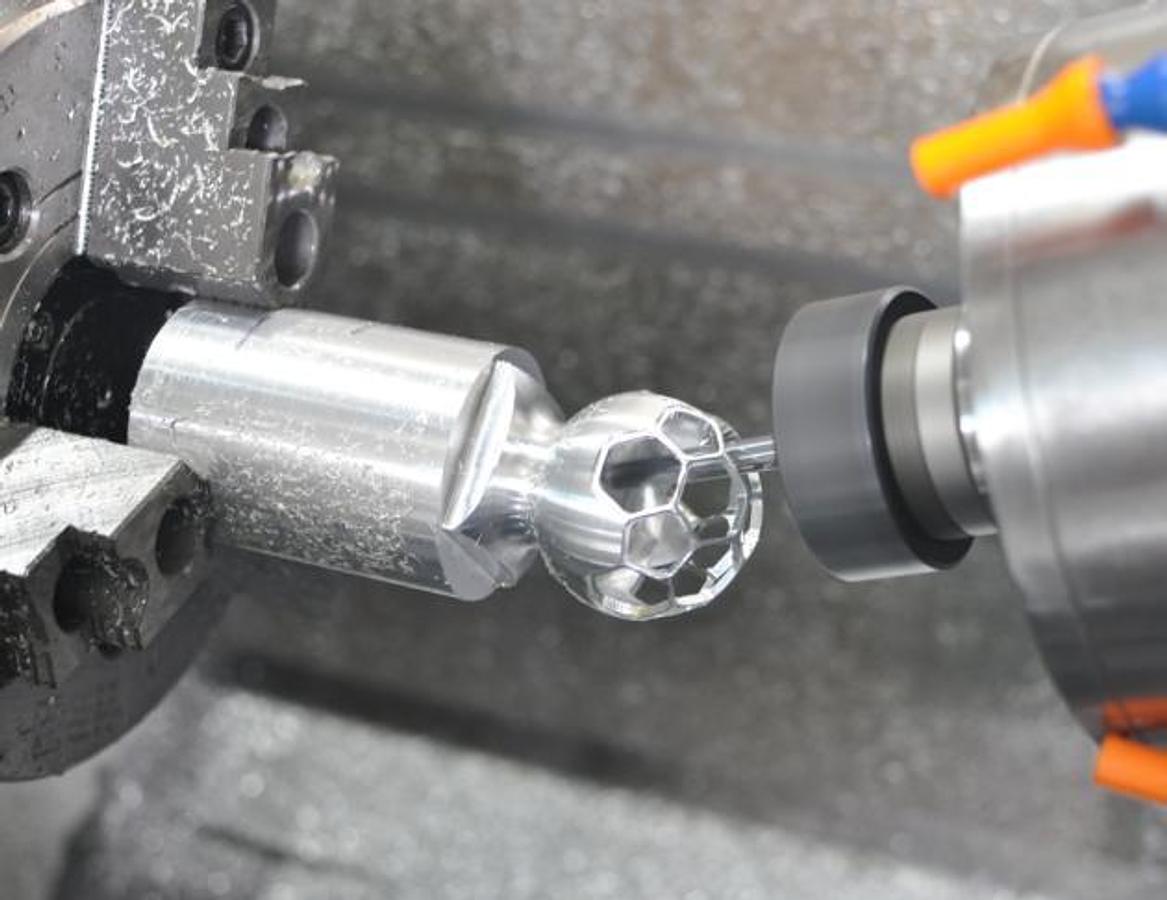

The MT-540 is a high-end seven-axis mill-turn center that combines X/Y/Z/W linear axes with A, B, and C rotary axes, allowing a full range of machining processes—turning, milling, five-face machining, and complex contouring—all on one machine. Its 4900-rpm main spindle with an A2-6 spindle nose delivers stable and reliable cutting performance across different materials. The KM63 milling system provides strong rigidity, while the B-axis offers up to 1920 N-m of torque for heavy-duty cuts and high-angle machining.

With a 36/72-tool automatic tool changer, 36 m/min rapid traverse speeds, and support for Siemens 840D or Fanuc controllers, the MT-540 significantly improves workflow efficiency and reduces part handling. The C-axis features 0.001° indexing, enabling precise contouring, off-center machining, and synchronized mill-turn operations.

The MT-540 is well suited for aerospace structures, automotive drivetrain components, medical device parts, semiconductor-related components, and any application that requires multi-angle, multi-process machining. It is designed to deliver true Done-in-One performance with high precision, high reliability, and maximum productivity.

Specifications

| Manufacturer | Ingenious Machinery |

| Condition | New |

| Chuck size (inch) | 8 |

| Maximum swing (mm) | Φ540 |

| Maximum machining diameter (mm) | Φ350 |

| Maximum machining length (mm) | 700 |

| Speed (rpm) | I20 |

| Spindle nose | A2-6 |

| Spindle bore dia. / Draw bar dia. (mm) | Φ62/Φ52 |

| Front bearing inner dia. (mm) | ΦI20 |

| Tool shank type (milling/turning) | KM63 |

| Milling spindle speed (rpm) | I2000 |

| Maximum milling spindle torque (N-m) | I60 |

| Milling spindle motor output (kW) | 29.3 / 35 |

| A-axis ( ° ) | 360° / I5° |

| B-axis ( ° ) | ±II0° / 0.00I° |

| Repeatability accuracy (sec) | ±3 |

| Maximum torque (N-m) | 580 |

| C-axis ( ° ) | 360° / 0.001° |

| Maximum output (kW) | I5 / 22 |

| X/Y/Z/w-axis rapid traverse (M/min) | 36 / 36 / 36 / 30 |

| Tool capacity (pcs) | 36 (72) |

| Max. tool length (mm) | 200 |

| Max. tool diameter (mm) | 80 |

| Max. tool weight (kg) | 5 |

| T-T (sec) | 5 |

| Siemens type | 840D (Fanuc 31i) |