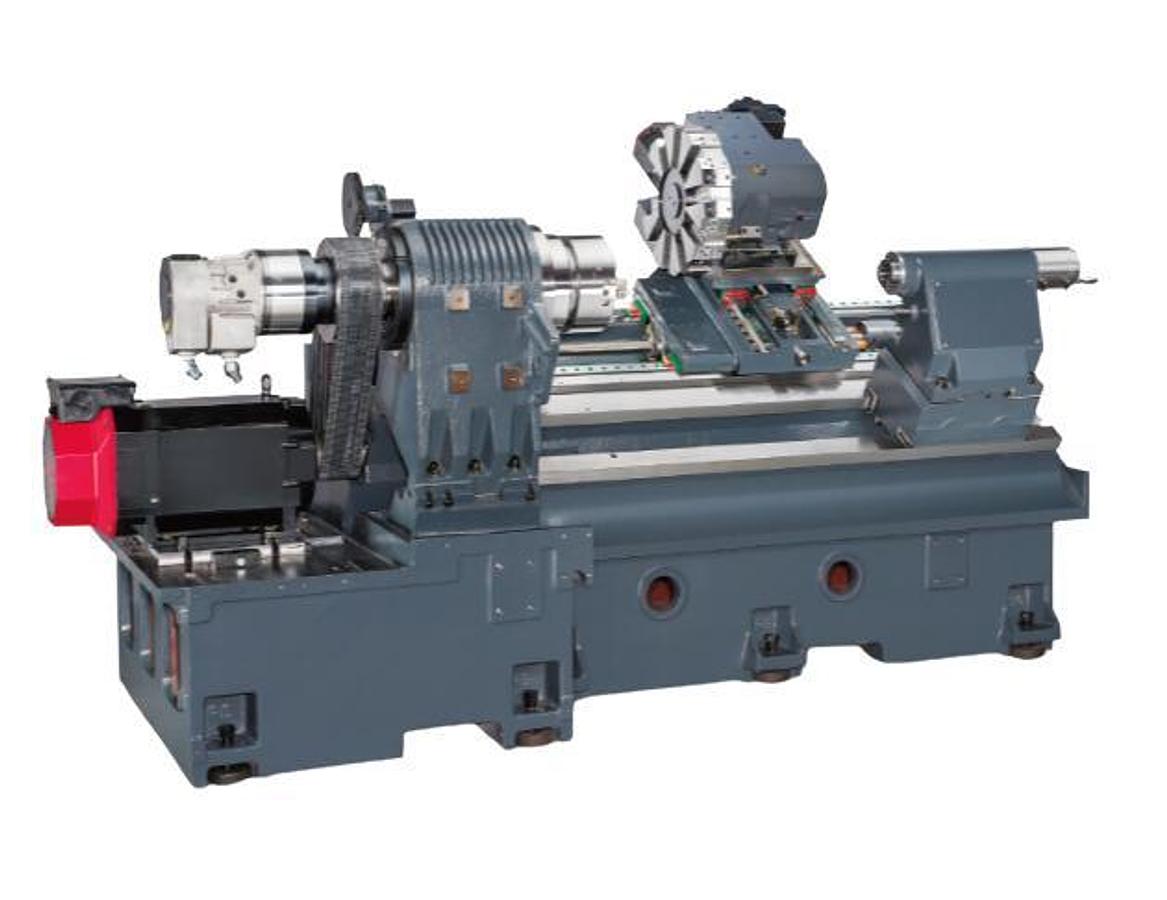

ML-600

Contact us for price

Specifications

| Manufacturer | Ingenious Machinery |

| Model | STD: LS-240 OPT: LS-240SV LS-200SP LS-200DTR STD: LS-240 OPT: LS-240SV LS-200DTR LS-200DTR |

| Condition | New |

| ITEM | UNIT ML-600S ML-600Y ML-600T ML-600TY |

| Standard | C axis Standard C axis |

| Swing over bed | mm Φ600 Φ600 Φ600 Φ600 |

| Swing over saddle | mm Φ450 Φ450 Φ450 Φ450 |

| Maximum machining diameter | mm Φ420 Φ340 BMT65: 380; VDI40: 285 Φ420 Φ340 BMT65: 380; VDI40: 285 |

| Maximum machining length | mm STD: 560 (8″); OPT: 540 (10″) BMT65 STD: 480 (8″); OPT: 470 (10″) VDI40 STD: 520 (8″); OPT: 510 (10″) STD: 475 (8″); OPT: 465 (10″) BMT65 STD: 450 (8″); OPT: 440 (10″) VDI40 STD: 475 (8″); OPT: 465 (10″) BMT65 STD: 450 (8″); OPT: 440 (10″) VDI40 STD: 475 (8″); OPT: 465 (10″) |

| Slant angle of bed | 30° 60° 30° 60° |

| X-axis | mm 230 (210+20) 225 (170+55) BMT65: 206 (190+16); VDI40: 206 (142.5+63.5) 230 (210+20) 218 (170+48) BMT65: 206 (190+16);VDI 40: 206 (142.5+63.5) |

| Y-axis | mm – ±50 – ±50 |

| Z-axis | mm 600 (8″); 590 (10″) BMT65: 525; VDI40: 565 600 BMT65: 450; VDI40: 495 |

| C-axis | ° – 360° (0.001°) 360° (0.001°) – 360° (0.001°) 360° (0.001°) |

| W-axis | mm – – 450 450 |

| Spindle speeds | rpm STD: 50~4,500 (8″); OPT: 50~3,500 (10″) STD: 50~4,500 (8″); OPT: 50~3,500 (10″) Main spindle STD: 50~4,500 (8″); OPT: 50~3,500 (10″) Sub-spindle 50~6,000 (6″) |

| Spindle nose | STD: A2-6; OPT: A2-8 STD: A2-6; OPT: A2-8, Built-in Spindle A2-6 STD: A2-6; OPT: A2-8, Built-in Spindle A2-6 STD: A2-5 |

| Spindle bore diameter | mm STD: Φ62 (A2-6); OPT: Φ86 (A2-8) STD: Φ62 (A2-6); OPT: Φ86 (A2-8) STD: Φ62 (A2-6); OPT: Φ86 (A2-8) Φ56 |

| Front bearing inner diameter | mm STD: Φ100 (A2-6); OPT: Φ120 (A2-8) STD: Φ100 (A2-6); OPT: Φ120 (A2-8) STD: Φ100 (A2-6); OPT: Φ120 (A2-8) Φ80 |

| Draw bar diameter | mm STD: Φ52; OPT: Φ75 STD: Φ52; OPT: Φ75 STD: Φ52; OPT: Φ75 Φ45 |

| Chuck diameter | inch STD: 8″; OPT: 10″ STD: 8″; OPT: 10″ STD: 8″+6″ (W); OPT: 10″+6″ (W) STD: 8″+6″ (W); OPT: 10″+6″ (W) |

| Type | Automatic Automatic – – |

| Stations | pcs STD: 10; OPT: 12 STD: 12 STD: 12 STD: 10; OPT: 12 STD: 12 STD: 12 |

| Square tool shank | mm 25 x 25 25 x 25 25 x 25 25 x 25 |

| Boring bar shank diameter | mm Φ40 Φ40 Φ40 Φ40 |

| Indexing time (0~180°) | sec LS-240: 1.4 (10T), 1.5 (12T); LS-240SV: 0.7(12T) 1.2 1.4 LS-240: 1.4 (10T), 1.5 (12T); LS-240SV: 0.7(12T) 1.4 1.4 |

| Spindle Speeds | rpm – 50~4,000 50~4,000 – 50~4,000 50~4,000 |

| Rapid Traverse | m/min X: 30, Z:30 X: 30, Z: 30, Y: 24, C: 200rpm X: 30, Z:30, W:24, C: 200rpm X: 30, Z: 30, Y: 24, W: 24, C: 200rpm |

| Quill diameter | mm Φ85 Φ85 – – |

| Quill bore taper | MT5 MT5 – – |

| Quill travel | mm 120 120 – – |

| Tailstock travel | mm 500 450 – – |

| Main-spindle | kw STD: α30ip (15/18.5); OPT: α22ip (11/15) STD: α30ip (15/18.5); OPT: α22ip (11/15) STD: α30ip (15/18.5); OPT: α22ip (11/15) STD: α30ip (15/18.5); OPT: α22ip (11/15) |

| Sub-spindle | kw – – α6 (5.5/7.5) α6 (5.5/7.5) |

| Live-tool | kw – α3/10000 (3.7/5.5) α3/10000 (3.7/5.5) – α3/10000 (3.7/5.5) α3/10000 (3.7/5.5) |

| Axis servo motor | kw X/Z – α12 (3.0) X/Y/Z – α12 (3.0) X/Z/W – α12 (3.0) X/Y/Z/W – α12 (3.0) |

| Hydraulic oil pump | kw 1.5 1.5 1.5 1.5 |

| Chip conveyor | kw 0.2 0.2 0.2 0.2 |

| Coolant pump | kw 0.8 0.8 0.8 0.8 |

| Positioning | mm ±0.004 ±0.004; Y: ±0.003 ±0.005 X/Z: ±0.005; Y: ±0.003 |

| Repeatability | mm ±0.003 ±0.003; Y: ±0.003 ±0.004 X/Z: ±0.004; Y: ±0.003 |

| Requirements | KVA 380-415/220V 26 KVA 380-415/220V 30KVA 380-415/220V 30KVA 380-415/220V 30KVA |

| Height | cm 185 228 186 228 |

| Floor space (WxD) | cm 401 x 214 441 x 233 441 x 214 441 x 233 |

| Packing (w/conveyor) | cm 389 x 212 x 212 402 x 229 x 255 402 x 229 x 212 402 x 229 x 253 |

| Net weight (w/conveyor) | kg 5,430 6,100 5,990 6,200 |

| Gross weight (w/conveyor) | kg 5,730 6,370 6,328 6,700 |