2025 Twinhorn VTH-1060L3

Description

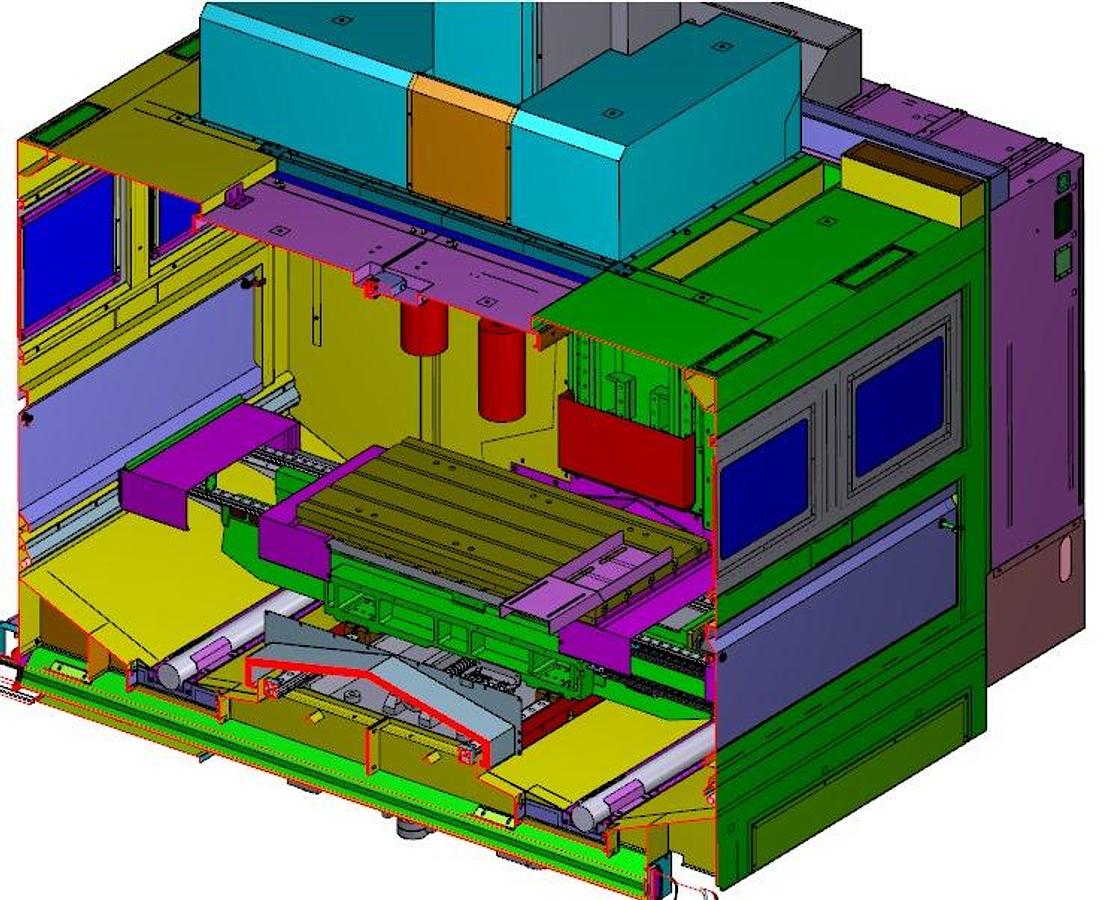

The 2025 Twinhorn VTH-1060L3 is a new vertical machining center designed for efficient factory operations. It features a FAGOR 8065 POWER control system with a 10.4-inch display, providing users with precise control over their machining processes. The machine is equipped with a BT-40 spindle taper and a belt-driven spindle capable of reaching speeds up to 12,000 RPM, powered by an 11/15Kw motor, ensuring high-performance operations for various machining applications. This machine includes a 24-tool automatic tool changer (ATC), allowing for quick changes between tools to maximize productivity. The table size is generously sized at 1200 x 600 mm, accommodating a range of workpieces. The travel dimensions measure 1020 mm on the X-axis, 600 mm on the Y-axis, and 600 mm on the Z-axis, all supported by a linear guideway system for smooth and accurate movement during machining processes. The Twinhorn VTH-1060L3 is built for heavy-duty industrial use, with overall machine dimensions of 3,370 x 2,765 x 2,870 mm and a robust weight of 7,000 kg, offering stability and minimizing vibrations during operation. It is an excellent choice for manufacturers seeking a reliable and efficient solution for their vertical machining needs.

Specifications

| Manufacturer | Twinhorn |

| Model | VTH-1060L3 |

| Year | 2025 |

| Condition | New |

| Stock Number | 00025 |

| Control | FAGOR 8065 POWER / 10.4" Display |

| Spindle taper | BT-40 |

| Spindle speed | 12,000 Belt drive |

| Spindle motor | 11/15Kw |

| ATC | 24 |

| Table size | 1200 x 600 mm |

| Travel | 1020 / 600 / 600 mm (Linear guideway) |

| Machine dimensions | 3,370 x 2,765 x 2,870 mm |

| Machine weight | 7,000Kg |